Jonesport Shipyard does what most other Maine coastal boatyards do day in and day out — build, maintain and repair boats for commercial fishermen and pleasure boat owners, and store them in the winter. Then there are the 1,500 covid-19 protective face shields the yard is building for Down East Community Hospital in nearby Machias. Even with the entire nation trying to cope with various levels of the covid-19 pandemic, building face shields is not something done in your average boatyard.

It started with Robert Alley, Jonesport’s representative in the Maine House of Representatives, coming by and asking for donations of N95 facemasks. “We had a couple of boxes and gave them to the hospital,” says Jonesport Shipyard’s owner Sune Noreen. Shortly after that, Noreen’s daughter reached out to the hospital and asked what they needed.

“Face shields” was the reply “and would we like to do that and give them a price?” says Noreen. He admits it was hard to come up with “a price for something we haven’t made before and not lose money on it — but we are making do.”

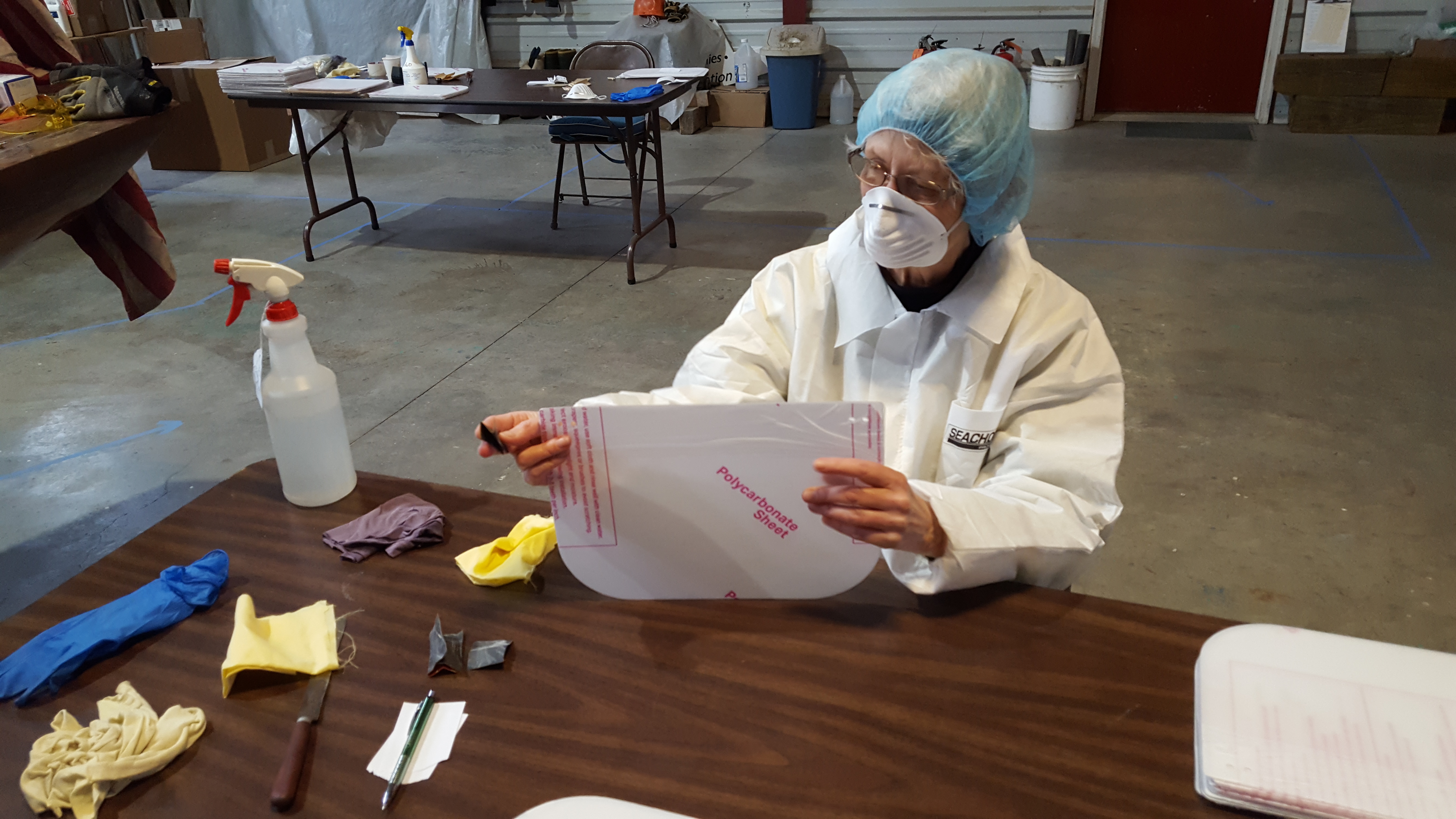

The face shields, made out of polycarbonate, protect the wearer’s face if they are sneezed on. Each shield gets three replaceable 1-1/2" x 10" foam pads that rest against the head and a head strap made from blue tourniquet material. The face shields are made in a special room “and we don’t let anyone in,” Noreen says, other than the person making the face shields, and they are wearing a white suit and gloves, eye protection and sneeze protection.

Covid-19 has also affected the daily boatyard routine. Only those working on boats are allowed into the buildings; employees don’t all work at the same time. “They are a little bit staggered,” says Noreen, which means jobs might take longer than normal, and though some yard workers and customers don’t want to wear masks or “think it’s silly, all are wearing masks. We are doing what the state mandates to stay open.”

That allows the Jonesport Shipyard crew to launch lobster boats like the 42-foot Willis Beal-built Papa’s Legacy that had been in storage for the winter, and the Son Seeker, a 46-foot Wayne Beal that was finished off by Taylored Boats in 2017. It too had been in storage for the winter but had bonding and wiring issues, broken terminal fittings, with some electrolysis that needed attention.

Noreen admits that as a result of working and living with covid-19 issues, “I haven’t felt this much fatigue in a long time.” But the launching of the two lobster boats was different: “That was kind of fun,” he says.

Mainely Boats in Cushing, about 130 miles down the Maine coast from Jonesport, had several boats in for repairs when it ran up against a covid-19 scare and shut down after one of its workers, who also worked in healthcare, became sick. “I didn’t know if she would have it or not, so I shut down things” for four weeks, says Mike Hooper, Mainely Boats’ owner.

But toward the end of April, Mainely Boats was “back up and running. Everything seems to be fine. She tested negative” for covid-19. But covid-19 continued to affect Mainely Boats, primarily in the time it took to get supplies. “Some of suppliers shut down, affected us being able to get stuff,” says Hooper. A case in point is the Mary B, a 47 Libby that was being built for Steve Budrow, a Rockport, Mass., lobsterman. Wheelhouse windows were ordered in February but did not arrive until mid-May.

One of the better-known boats along the Maine coast — especially when you are talking lobster boat racing — has been Tommy Clemons’ Motivation, a 36 Northern Bay. Well, Clemons sold Motivation to Vinalhaven Island’s Alfred Osgood, another longtime lobster-boat racer, who is having Mainely Boats replace Motivation’s 1,000-hp Cat C18 with a 1,400-hp MAN with twin turbos that was being rebuilt by Mid-Coast Diesel Performance in Warren. “It’s a race motor,” says Hooper, an obvious understatement.

To further enhance its racing performance, Mainely Boats is adding a double set of lifting rails to the hull and all through-hulls on the bottom are being flush mounted. “It’s a flat seamless screen so nothing is hanging out on the bottom of the boat,” Hooper says. “There’ll be less drag.”

Among the lobster boats in for repairs are the Independence, a 42 Duffy from Vinalhaven Island, and a 35 Duffy that came up from Connecticut. The Independence is getting a new wheelhouse floor, alterations done up forward, and the hull will get a coating of Awlgrip. The 35 Duffy is having its 6-cylinder Cat pulled and replaced with a 220-hp John Deere 4045. She’s also having new wiring installed and a coating of Awlgrip. “It’s pretty much a complete face lift,” says Hooper. He figures the 35 Duffy was probably built in the late 1970s.