Sometimes it’s the simple ideas that make working on deck less arduous, painful or just plain safer. I’m told that back in the 1960s fishermen, especially halibut longliners in the Pacific Northwest and Alaska, wore only a heavy cotton glove for coiling gear, dressing and icing fish and working the roller, where they constantly were clearing gangions from around the incoming groundline. That meant their hands were always wet.

The extension welded to the top of the winch's pivot bar keeps the fisherman several feet away from the drum. NIOSH photoThe early 1900s dory fisherman Charlie York said he would rather wear nippers on his hands — when asked to choose between heavy cotton gloves, woolen mittens and nippers —because “as long as salt water is comin’ onto your hands, they won’t freeze,” (see “Charlie York; Maine Coast Fisherman” by Harold B. Clifford) But it is no fun longlining for halibut where your hands are constantly wet and cold.

Sometimes when a fisherman woke up after a turn in his bunk with hands so stiff and racked with pain that — an old time fisherman told me — the only relief came after he peed on his hands.

Then someone came up with the idea of wearing the rubber gloves that housewives used when washing dishes. A few probably resisted because the gloves were such a womanly thing, but fishermen started wearing the rubber gloves — they were mostly yellow — under the cotton gloves. That pretty much solved the problem of painful, sore, stiff hands. Not completely, but it was a whole lot better.

That leads us to level winds and winches, especially deck-mounted winches the crew is working around. The danger, of course, is being pulled into the winch by incoming wire. Level winds keep the wire under control to some extent, while aligning it evenly across the net drum.

There are two basic kinds of level winds, a mechanical level wind that doesn’t require any work on the part of the fisherman and the pivot bar. The fisherman has to push on the pivot bar, forcing the wire to lie flat on the drum.

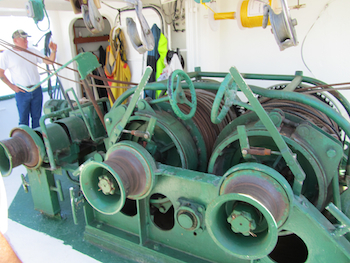

The pivot bar is the potential problem because you are leaning over the drum and can get wrapped up in the wire. Then a fisherman came up with the idea of welding a dog-leg extension on the pivot bar. Now, instead of leaning into the winch drum when pushing on the bar, you are 2 or 3 feet farther away from the drum and wire.

The photo shows the dog-leg extension on a double-drum winch, but an extension can just as easily be welded to the pivot bar of a single-drum winch.

There you have it, two simple ideas that don’t have to come out of a research lab at MIT. Just look around, ask if there isn’t a better way, and you just might find it.