Rolls-Royce announced this summer that it is expanding U.S. manufacturing capabilities with a $75 million investment in its Aiken, S.C., engine plant for mtu Series 4000 production.

The investment will increase machining capabilities and grow the facility’s footprint, creating 60 new jobs in the U.S. with a total of 434 full-time positions at the facility. The South Carolina Coordinating Council for Economic Development approved job development credits related to the project.

"The increased investment strengthens our ability to serve our U.S. customers – especially in the fast-growing American data center industry,” Adam Wood, managing director, Rolls-Royce’s power systems division in America, said in a statement announcing the Aiken expansion. “By increasing our machining capabilities in Aiken, we can supply more engines to Mankato, enabling us to deliver more gensets with shorter lead times. These investments reflect our commitment to supporting U.S. customers with reliable, locally produced solutions.”

Earlier this year, Rolls-Royce announced a $24 million expansion of its Mankato, Minn., facility, adding 100 jobs to its power systems division in the U.S. These investments reflect the rapid growth of data centers in the U.S., increasing pressure on electric grids and the critical need for reliable power generation.

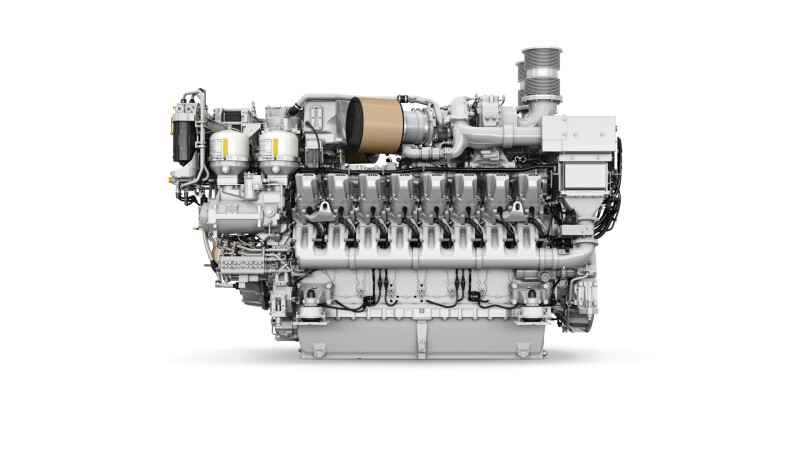

Demand for high-power mission critical backup generators from Rolls-Royce has grown considerably over the past decade. The mtu Series 4000 engines that power these systems are built in Aiken and then assembled into complete generator sets at the Rolls-Royce facility in Mankato.

With this investment, Rolls-Royce will machine additional mtu Series 4000 components in the U.S. Currently, most of the components are machined in Germany and sent to the U.S. as finished goods. To meet demand, additional in-country machining is essential, the manufacturer said.

Since the start of production in 2010, Rolls-Royce’s Aiken campus now encompasses a 395,000 sq. ft. campus with state-of-the-art production capabilities, an engine testing facility, office space, a research and development center, four large engine test stands and a remanufacturing and overhaul center. In 2017, the company added a 1.35 MW ground-mounted solar array on approximately seven acres and has an additional microgrid that generates enough solar power from panels on its covered parking lot to supply its entire administration building.

The facility will be expanded in two phases. Phase one will grow the existing manufacturing footprint by 37,000 sq. ft. In a potential further phase, another 22,000 sq. ft. of manufacturing space could be added (60,000 sq. ft. in total). Construction for Phase 1 will begin in Q1 2026 with production set to begin in July 2027.