Robots are cutting up snow crabs in Canada, a sign of things to come in the seafood processing industry.

Overall, seafood processing has a relatively small robotics investment. Robots have yet to make it into any of Alaska’s 176 fish processing shops. But the lure of reduced production costs, increased fish quality and crews of worker-bots is turning the tide.

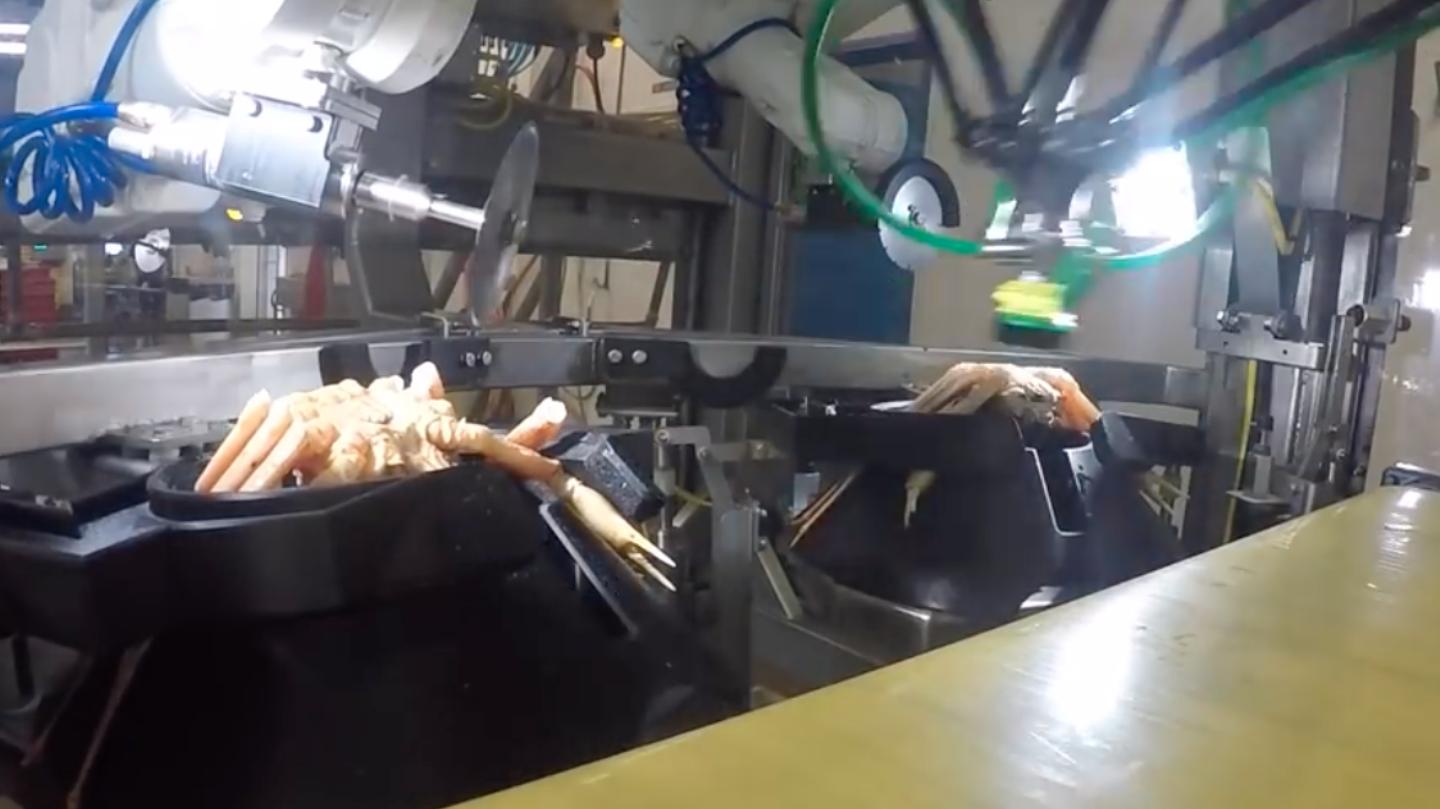

The CBC reports that the world’s first crab plant robot began work this spring in a plastic chamber about the size of a shipping container in remote Newfoundland. The robot receives crabs on a conveyor belt and quickly dismembers each with a buzzing blade. The crab legs then tumble into a tub below, all sorted, sectioned and ready to go.

Another robot in the works will soon shuck all the meat from the crab for a better financial return.

“Instead of sending our crab out as sections with the meat in the shell, we thought we could attract a higher price if we sold the meat instead,” said Bob Verge, director of the Canadian Center for Fisheries Innovation where the crab cutting robots were created.

The meat extraction used to be done by hand in Newfoundland plants, but years ago that job shifted to China where the labor is cheaper.

Bringing that step back to Newfoundland, Verge said, would make more money for plant operators and get more value from the resource.

And for the first time robots also are deboning and filleting cod on Norwegian processing lines. New Atlas reports that a machine called Apricot (automatic pin-bone removal in cod and whitefish) is using X-rays to locate the tiny pin bones in the fish water jets to trim them away.

The design of the automated filleting machine developed by the APRICOT project.

“Unlike farmed salmon, which are similar in size and shape and therefore suitable for automated machine filleting, the variability of wild-caught whitefish such as cod has kept filleting of these fish a manual affair,” said a spokesman for Marel of Iceland, the world’s biggest fish processing equipment manufacturer.

The Apricot robot system is expected to be ready for commercial use by year’s end.

Robot makers hope their machines will help solve workforce problems in fish plants caused by changing demographics, global markets, labor shortages and eternal visa-program red tape. In the near future, they predict more highly skilled humans will work on sophisticated machines and computers, and not on the slime lines.

“If we are going to attract young people, we need better jobs, not more jobs,” said Verge. “We have to offer them a better deal. We’ve already demonstrated this technology to young people, and they are very impressed with it. They say, ‘I’d like to do this.’”

Robots also are making inroads into the big freezers that hold the bulk of Alaska’s seafood before it goes to markets.

A Netherlands company called NewCold has partnered with Trident Seafoods to build one of the nation’s biggest cold storage warehouses outside of Tacoma, Wash. The companies call it “a solution for increased labor, land and energy costs.”

Seafood products will be stored on a robot-run system of tiered trollies and racks in low oxygen and in pitch dark, and then transported to the loading area by conveyors and worker-bots.

When the $50 million project is completed at year’s end, it will have storage capacity of more than 25 million cubic feet.