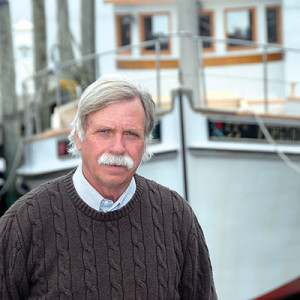

When Ronnie Bevins, of Bevins Oyster Co., Kinsale, Va., needed one of his boats rebuilt, he turned to Larry Jennings of Jennings Boatyard in Reedville, Va. The oysterman’s 32’ x 10.5’ fiberglass deadrise, originally built in 2006 by Ronnie Carmon of Crisfield, Md., was due for a major overhaul.

Bevins Oyster Co. is one of Virginia’s largest oyster growers, leasing oyster grounds on all the state’s major rivers. The firm’s many commercial fishing boats are worked often and hard.

“When Ronnie (Bevins) brought the boat to me most everything on the top sides needed work - but her hull was good.” says Jennings.

The boat was gutted down to its bare hull and the entire superstructure, house/pilothouse, decks, etc. were replaced. The boat was originally built with glass over plywood, and over the years much of the topwork had been compromised, says Jennings.

“She had a monster house and pilothouse on her,” says Jennings. “We took all that off and designed and built a shorter, more compact house which gives the boat more workspace on the aft deck for working oyster dredges and to carry more payload.”

The new decks and washboards are coated with double layers of 1708 biaxial fiberglass cloth/resin. The superstructure, including longitudinal stringers and transverse bulkheads, were all replaced with Marine Coosa Board, a foam core material that is 30 to 40 percent lighter than plywood and isn’t susceptible to water rot, says Jennings.

Bevins grows oysters in both shallow and deep water. His boat was originally powered by a Volvo Penta outdrive diesel engine, which gave him the ability to raise and lower the prop to the desired water depth.

Jennings pulled all that out and filled in the outdrive hole in the stern, beefing up the stern’s structural strength to hold a Stainless Marine aluminum bracket, jacking plate and an outboard motor. The hydraulically driven jacking plate allows the outboard motor to be raised straight up and down six inches each way.

The plan was that Bevins’ boat would be powered with an outboard Yamaha 300 hp, which was sitting in its box at the yard ready to go on the boat. The box had to be opened early, however, as Bevins had an old outboard engine blow up on one of his other working oyster boats.

“Now, he is looking into the possibility of an OXE Diesel outboard as a replacement to the Yamaha,” says Jennings. “If he goes with a diesel outboard, it would be the first one that I’ve heard of on a commercial fishing boat in Virginia’s portion of the bay.”

Jennings has also designed and is building a mold for a 27’ x 10.5’ deadrise hull. He has partnered with Jett’s Marine, Inc. of Reedville, who plans to market the boats to commercial and recreational boaters.

“The commercial fishing boats will have a side console for working pots and other gear while recreational vessels can have a standard house and pilothouse forward or not,” says Jennings.

The mold is just about finished and production is planned in the coming months. “I am going to build them and Jett’s Marine will market them,” says Jennings. “I will do what I do best and they will do what they do best.”