Expanded marine engine lineups and concessions on tier requirements give fishermen a wide playing field for power options

Despite the general economic slowdown resulting from the covid-19 pandemic, there is a lot going on in the world of marine engines across the board, from a new Oxe diesel outboard to a rollback of Tier IV regulations for some vessels.

According to Chris Ponnwitz, marketing specialist at Mack Boring & Parts Co., the Somerset, N.J.-based company will be distributing and supporting the new Oxe 300-hp diesel outboard this year.

“We have seen a lot of interest in the commercial fisheries market, and this new 300-hp model from Oxe Marine will further expand their line-up, which starts at 125 hp. We are excited to see new market penetration for vessels and fishermen that are looking for a higher output torque and hp power plant.” According to Oxe the 300-hp diesel outboard now available in the United States is a bi-turbo configuration that provides 443 foot-pounds of torque at the crankshaft at 1,750 rpm, and 369 foot-pounds at 1,000 rpm, providing a high degree of bollard pulling power and rapid acceleration.

Mack Boring has put many 13- and 16-liter Scania engines in lobster boats throughout New England.

“That’s probably our most saturated market,” says Ponnwitz. “We have had a lot of success in the lobstering market with the newer 800 XPI engine, and we are looking forward to Scania breaking into the recreational market with their new 900 -and 1,150-hp models.”

In between the Oxe and the Scania, Ponnwitz expressed excitement about two new Yanmar engines Mack Boring is now distributing.

“Yanmar just announced the 6LF and the 6LT engine series,” he says. “With up to 550 hp out of the 6LF up to 640 hp out of the 6LT series, we are now seeing an opportunity to expand our already die-hard Yanmar customer base and open up more of the market to the reliability and support from Yanmar.” According to Ponnwitz, these new Yanmar common rail, in-line 6s might be a good fit for lobster boats and other small-boat fisheries.

Farther down the East Coast, Motor-Services Hugo Stamp, in Fort Lauderdale, Fla., offers Baudouin Reman remanufactured engines, which are becoming quite popular.

“There’s a lot of old iron out there,” says Torsten Schmitt, sales specialist at MSHS. According to Schmitt, Baudouin is taking back old engines and rebuilding them. “They’re affordably priced,” says Schmitt. “With a two-year warranty, it makes them very attractive for fishing boats customers who are thinking economically, don’t want to spend the money for brand new engines, but are tired of the older fuel-hungry engines.”

MSHS offers the Baudouin Reman 15.9-liter engine with ratings from 600 hp @ 1,800 rpm to 815 hp @ 2,100 rpm.

On Aug. 26, 2020, the Environmental Protection Agency changed the Tier IV rules requiring aftertreatment systems to reduce emissions on engines over 815 hp. Many fishermen building vessels wanted more than 815 hp but could not fit aftertreatment systems, so the EPA relented. According to Schmitt, MSHS is also selling the Fiat Powertrain C16-1000.

“Since the EPA changed the rules, we are now able to offer the FPT C16-1000 (15.9l inline 6) with 1,000 mhp commercially. Fishermen want the horsepower, and now we can give it to them. These engines are in high demand.”

Schmitt points out that FPT is working on the calibration so the engines will be commercial EPA compliant at 1,000 mhp.

“You can also retool pre-rule change engines,” says Schmitt. “You still have to apply to the EPA for an exemption, but we can do in-the-field modifications.”

Besides lobster boats, Bristol Bay salmon gillnetters — limited to 32 feet — also want to pack a lot of horsepower into a small space.

While MSHS is rebuilding Baudouins for draggers, longtime Maine draggerman Marshall Alexander recently repowered his 54-foot dragger, the De Dee Mae II, with a Cummins X15.

“450 horsepower,” says Alexander. “They had to cut it down from 500 because you can only go up 20 percent, see. But I’ve got a 4-foot nozzle on her, and a 4.5:1 Twin Disc 514 Omega gear on there, and we pitched the wheel all we could. She was 48-inch square, and we upped the pitch to 52. She tows a 100-foot net with 50 fathoms of ground gear, no problem.”

Alexander is more than pleased with the fuel efficiency.

“Dock to dock we averaged 7 gallons an hour,” he says. “The only problem we had was the temperature. It got up to 160 degrees in the engine room, and it’s only supposed to be 100. We set up a blower, and that solved that problem.”

The EPA rule change has helped many fishermen get the horsepower they want in the space they have. According to Jim Mundth at Caterpillar, vessels that have the space may be better off using an aftertreatment system.

“You see, when we went from Tier II to Tier III, we reduced emissions by retarding the timing and injection so the fuel burned cooler. The thing is, the NOX goes up with better combustion.” Mundth says the shift to Tier III actually reduced fuel efficiency.

“By 5 to 8 percent! With the switch to Tier IV, we’re getting that back,” Mundth says. “Tier IV requires aftertreatment of the exhaust. We reduce NOX by injecting urea into the SCR (selective catalytic reduction). Vessels that have the space are moving to Tier IV because the fuel savings offset the cost of the urea.”

Mundth notes that vessels that use Tier IV engines with aftertreatment have to allocate tank space for the urea, usually around 10 percent of the volume of the fuel tank. “But they have more space because they’re burning less fuel,” he says.

On the West Coast, Rich Murdy, marine sales manager at Pacific Power is excited about the Volvo Penta D16, a 16-liter, inline 6-cylinder engine. “It’s going to be a big deal,” says Murdy. “Volvo Penta is doing a facelift on the D16. It was 750 hp, and they’ve bumped that up to 800. The 750 was maximum but now it’s rated as continuous.” Murdy sees a potential market among limit seiners and larger crab boats. He points out that Volvo Penta’s D16 also has potential as a 550-kW genset.

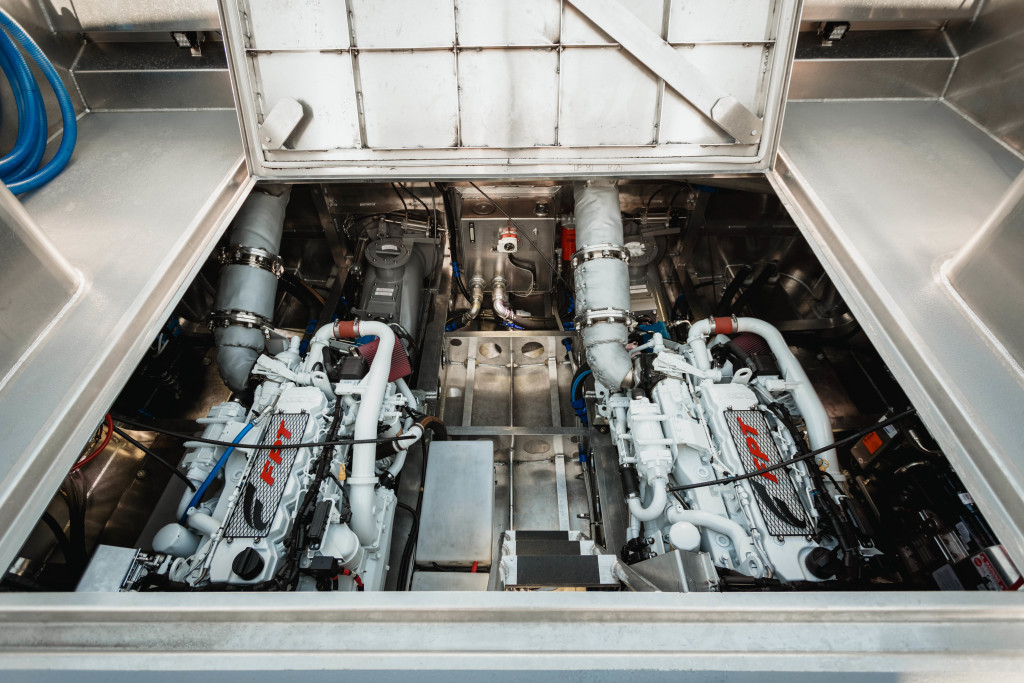

“Another engine fishermen love is the D8,” says Murdy. “Ed Oczkewicz up at Maritime Fabrication, La Conner (Wash.), put two in a Bristol Bay boat they just built. That’s a 550-hp full keel-cooled engine. And they’re light, 1,900 pounds.”

Pacific Power is also a Detroit Diesel distributor, but they do not sell any. “None,” says Murdy. “But we rebuild them all the time — 671s, 692s, 1271s — I don’t know how many in a year, but I’d say it’s in the double digits every month.”

Many fishermen choose John Deere engines for their value, and the company’s 13.5-liter 6135SFM85 powers many vessels in the United States and commercial fishing fleets around the world. Beyond meeting performance needs, John Deere is offering hardware solutions to meet market demands with its 13.6L engine, which includes a no-DPF solution for Final Tier IV variable- and constant-speed markets.

In addition, John Deere is unveiling its new 18L engine in 2022. Building on the 13.6L engine design, the 18.0L engine offers maximum power over 650 kW (870 hp). It was also designed with flexibility, serviceability and durability in mind.

“We wish they’d done this 10 years ago,” says Glenn Dobbs, territory manager at Western Power Products in Long Beach, Calif. “We’ve been wanting a thousand-horsepower engine from John Deere for a long time.” But fishermen may have to wait.

“The 13.6 is coming out in 2021, and the 18-liter in 2022. You’re going to see those engines in tractors first, then power generation, and last on the list is marine sales, because of the numbers,” he says.

According to the manufacturer’s website, the 18-liter is equipped with John Deere engine controls, a high-pressure common-rail fuel system and series turbochargers. It also uses cooled EGR (exhaust gas recirculation.) The model-based controls enable advanced prognostics capabilities and improved transient response. A rear gear train reduces noise as well as torsional and crank stress. The top 20 service and repairs for larger John Deere engines were also taken into consideration when designing the engine to ensure ease of serviceability.

With engines and EPA emissions requirements coming into alignment, marine diesel engine manufacturers are more able to give fishermen the power they need while conforming to regulations.