Mustad’s new E-Line autoline system meets a growing demand for electric deck gear.

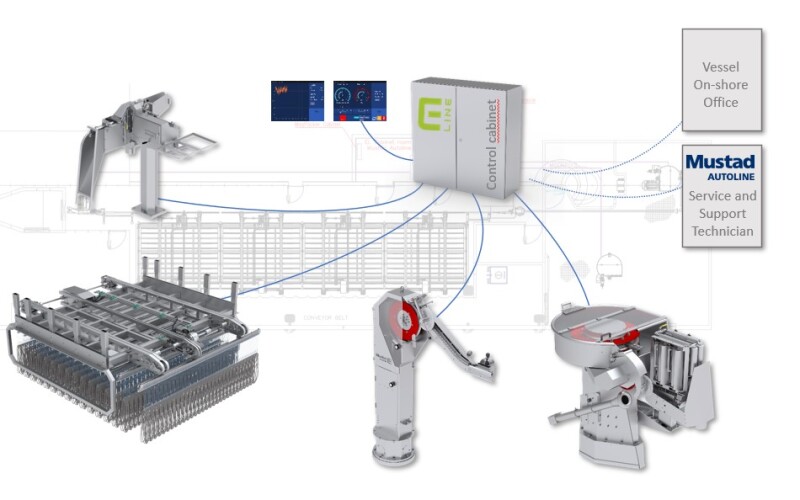

For longline fishermen seeking more precise operational capabilities and a cleaner, quieter work environment, Mustad Autoline has introduced its new E-Line electric autoline system. “The E-Line package is built on the drive technology used in (Mustad’s) SuperBaiter,” says Josh Dunham, Mustad general manager for North America. “It starts with our hauler and hook cleaner, run by a Siemens drive control system.”

The Mustad MA HH 4000 E-Line hauler is a beast. Weighing well over a ton, the 80-inch by 51-inch hauler is adjustable in height anywhere from 59 inches to 71 inches. Included in this footprint is the rotocleaner and line retriever. With a 27 ½-inch sheave diameter, the hauler, powered by a Siemens 32-amp/36kW motor, can wind in 500 feet of line per minute.

“The system is designed for boats over 70 feet, hauling up to 80,000 hooks per day,” says Dunham. “For an 18-hour hauling day, that’s 0.8 seconds per hook.”

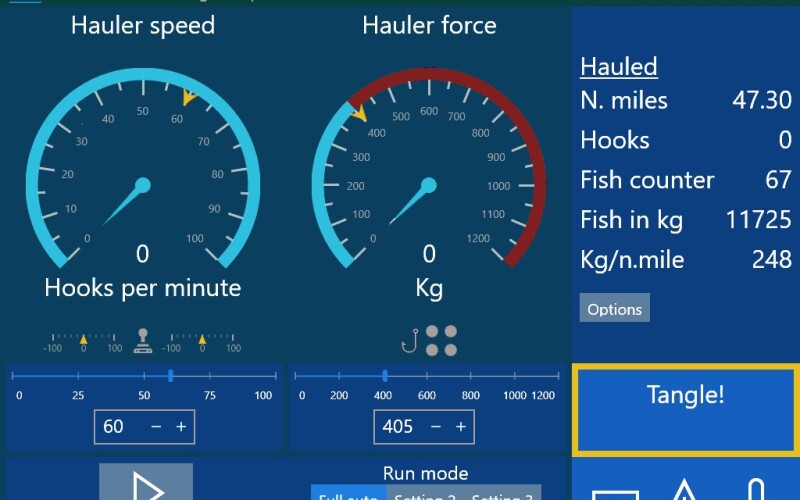

As Dunham describes it, the hook cleaner has four brushes that move slowly up and down while rotating for even wear. “The hauler and the line retriever have a programable logic controller to keep tension steady when hauling in rough weather. It can sense a 5-kilogram change in the tension and adjusts the hauling speed and force accordingly.”

The result is more fish, according to Norwegian skipper Ståle Dyb, who is using the system. “When the vessel goes up on a wave,” says Dyb, “the line almost stops, and when the vessel goes down it picks up again.” Inconsistent tension has been found to lead to more fish shaking off the hook when the line goes slack. The dynamic tensioning of the E-line hauler keeps the line speed consistent under water so that fewer fish are lost.

From the hauler and cleaner, the hooks go to a hook separator that uses eight compact and powerful magnets to sort the hooks and slide them onto a magazine. The line retriever and hook separator also keep up with the varying tension and speed of the hauler. “There is still some coiling by hand,” says Dunham. “The gear has a memory and will coil itself, but it needs some babysitting.”

The hooks on the magazines are inspected and straightened, offset, or replaced as necessary and from there go onto a carousel from which they can be accessed and loaded automatically when setting.

Mustad’s SuperBaiter has been available since 2005. The MA BM 6000 SuperBaiter can be set to cut bait at a predetermined size and can bait up to 6 hooks per second. “Typical setting speed is 8 to 9 knots,” says Dunham. “And it depends on the hook spacing. Usually for groundfish the spacing is 1.2 meters between hooks, but some Norwegian vessels are going to 1.4 meters.”

One crew member places the bait, such as whole squid or herring, on a spiked conveyor chain that feeds it into the SuperBaiter. The hooks passing through the machine trigger a knife to cut the bait, and the hook is then pulled into and doubled onto the cut piece of bait.

“It can bait circle hooks, offset hooks, or J hooks,” says Dunham. “There’s an infrared sensor that monitors if the hooks are being baited - usually it’s about 98 percent of the hooks. If it gets to 90 percent or lower, you know something’s wrong and you need to take a look. Our line controller [JD1] gives the operator another tool to ensure that the equipment is functioning at peak efficiency.”

According to Dunham, the drive system that has been used in the SuperBaiter for nearly 20 years is the basis for the rest of the E-Line system. “When I say that the E-Line system is built on this system, what I mean is the sensors, the line controller software and the machines. Everything is connected, it is all controlled by a common PLC (Programmable Logic Controller) from one supply cabinet. We can monitor over 1000 different parameters - the temperatures of the motors, power consumption, vibration, frequency oscillation. If a bearing in a gearbox is getting worn, through machine learning algorithms we can let you know if and when it needs to be replaced.”

Dunham adds that the complete E-Line system can be monitored and adjusted by Mustad’s technicians via satellite link if needed.

According to skipper Dyb using the system in Norway, the E-Line system is more comfortable, and the power consumption is lower than that of a hydraulic system. “The electric motor runs without noise,” says Dyb. “It is much more comfortable to work in less noise, the crew confirms. That was their first reaction to the new unit. And the electric system is less energy consuming. We calculate a savings of about 20 tons [5,633 gallons] of fuel per year.”

Dunham reports there are currently five boats using the E-Line system, and two more about to install it. “I should note that we are also going to make this for our Coastal System, for boats under 70 feet,” he says. “That should be available in late 2024.”