Ed Oczkewicz built his first through-picker gillnetter for the Bristol Bay salmon fishery in 1997. “Back then only a few of us were doing them,” he says. “Now they’re trendy.”

Oczkewicz’s second through-picker, the Dan O, can operate as a bow picker or stern picker when hauling back a gillnet. The wheelhouse sits elevated on port and starboard supports called findleys. The drum is on rails so it can slide forward when stern picking.

Oczkewicz started building boats in 1978. “I went to college, but I always wanted to just build stuff,” he says. “There was a big boatbuilding boom in the late ’70s and ’80s. So I started Maritime Fabrications. Just baby steps. I didn’t want a lot of debt. But eventually we bought the property and equipment of La Conner Machine and Drydock and became La Conner Maritime Services.”

Wanting to deliver a superior product, Oczkewicz headed to Bristol Bay to see what fishermen wanted in a vessel. “I hopped on a boat in 1983, maybe ’82. It was an eye-opener,” he says.

Oczkewicz kept going to Bristol Bay for the next 15 years, eventually taking his own boats and selling them.

“I took six years off after 1997, took my family out fishing,” he says. “But when my son Isaac got old enough, I got back into it.”

At age 39, Isaac Oczkewicz now runs Maritime Fabrications, the boatshop at La Conner. Oczkewicz notes that another of his four sons runs the manufacturing arm of the business, and another started running his own gillnetter in Bristol Bay at age 19.

At 72, Ed Oczkewicz was considering getting out of the business, but he couldn’t do it.

“I sold my last boat, and somebody wanted to buy all my gear. I thought about it, but two weeks later I started building this one. Six and half months later, we got her up to Alaska.”

Oczkewicz called the original naval architect, Rick Etsell, to help with the redesign. “He’s retired and didn’t want to do it, but I was persistent, and finally he said OK.”

According to Etsell, Oczkewicz made it easy to say yes.

“Ed is a joy to work with,” Etsell says. “He knows what he wants and how to get there. Really all we did was modify a previous design of the first through-picker he did. We scaled it up, made it a little wider, and rearranged the weights — the batteries, the tanks. The extra width made it pretty easy to fit everything.”

Etsell used a program called Aerohydro to determine the hull lines and create developable surfaces, that he then put into 2-D CAD files.

“Ed has a great in-house design team. I did the part definitions, and they nested them,” he says of the process for creating the cut files.

“We made her two feet wider,” says Oczkewicz. “But you know, one day it was sunset and flat calm, and I took her out to see what she could do. I had her at 42.4 knots.”

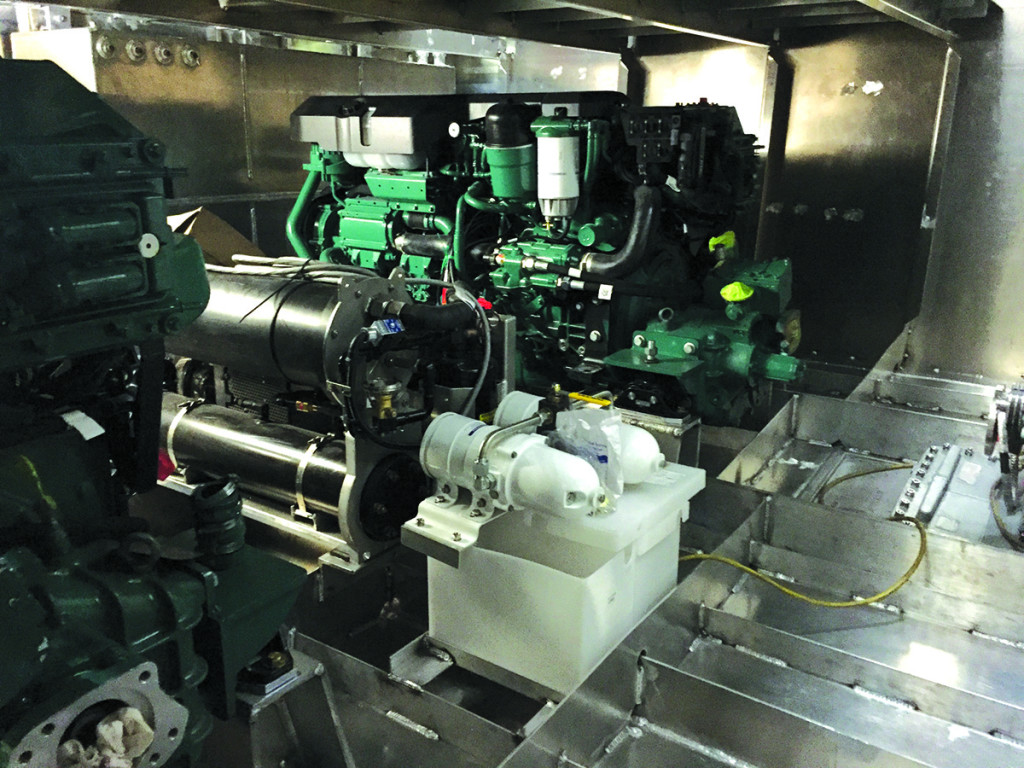

To get the Don O up to that speed, Oczkewicz powered his new boat with two 550-hp Volvo D8s with ZF 286 gears driving two Hamilton HTX30 jets at a ratio of just a little more than 1:1.

“The Hamiltons are a little more expensive,” says Oczkewicz. “But they’re the best, and have the most parts available.” Cruising, Oczkewicz can run at 35 knots at 2,300 rpm.

PTOs on the ZF gears drive two hydraulic 4.8-cubic-inch pumps.

“One for the RSW, and one for the deck equipment,” says Oczkewicz. “Usually the port runs the deck equipment and the starboard runs the RSW. But they are attached to a manifold so that if one of the engines flamed out, you could transfer the power, especially to the deck equipment. The important thing is to get the net back, right?”

Pac West supplied the 10-ton RSW system for the Dan O.

“It’s bigger than what I usually put in a boat. But the openings are getting shorter and more frequent. I wanted a quicker chill time to get that temperature down as soon as we start putting fish in, especially when you get a big day,” says Oczkewicz.

A companionway in the starboard findley and a hatch near the transom provide access to the engines and RSW compressor. Forward of the engines, Oczkewicz put two 225-gallon fuel tanks with a hydraulic reservoir between them.

“Some people put the fuel tanks in the middle and the fish holds next to them,” says Oczkewicz. “But I wanted to distribute the weight this way.”

He recalls that his first through-picker was trimmed differently and would not plane well. He put trim tabs on it and saw improved performance. So he put trim tabs on the Dan O.

“We only use them to get the back up. Once she’s up, we don’t use them, or you start to drive the bow down,” he says.

The fish hold is forward of the tanks. “It’s 500 cubic feet,” says Oczkewicz. “At about 45 pounds per cubic foot, what’s that give you? A little over 20,000 pounds. We use Nomar brailer bags. They’re a good company, up in Homer, family owned.”

The Dan O has crew quarters forward.

“It’s got a generous fo’c’sle,” says Oczkewicz. “There’s four bunks, a settee, a full galley, refrigerator and propane stove.” A 2,000-watt inverter drawing on two 24-volt banks, consisting of 4 6-volt golf cart batteries each, supplies AC power for the galley.

Up on deck all the machinery is Maritime Fabrications. It’s Oczkewicz’s specialty.

“The through-picker design gives you the option to be a bow picker or stern picker. The bow roller is 36 inches with a 14-inch core. The stern roller is the 38-inch with a 16-inch core. It’s what we market as the Big Bay, my son designed it.”

To further facilitate the option of picking from the bow or stern, Oczkewicz’s four-shackle drum can rotate and is on rails that allow it to slide 16 feet forward when picking from the stern. According to Oczkewicz, the advantage of having a picking option comes when fish are in shallow water or other boats are close.

“I sometimes set over the stern then pick over the bow,” he says, noting that picking over the bow gives him more control and allows him to pick closer to shore.

“The anchor winch is a new design,” says Oczkewicz. “I made it narrower and with a bigger diameter. That way you don’t have to risk getting your hand caught in it guiding the anchor rode on. Because it’s narrow, it just spools right on.”

Up in the pilothouse, accessed through the port findley, Oczkewicz has two Garmin plotters.

“I have a 10-inch and a 12-inch screen. I like that a lot, because I like to use the [Garmin] radar and the plotter at the same time,” he says. Oczkewicz also has two Icom VHFs and an Icom 2-meter VHF.” According to Oczkewicz, two meters is the wavelength of the VHF, and fishermen in Bristol bay use the 2-meter VHF to give themselves more communications options. “The 2-meter runs at a frequency close to your standard VHF. The antenna looks the same but is actually half an inch shorter.”

Besides the four bunks in the fo’c’sle, Oczkewicz also added a bunk in the pilothouse. But he notes, in the rush to get to Bristol Bay for the 2020 season, such as it was, a lot was left undone. After the season, he put the Dan O on a barge and sent her home to La Conner.

“We’re finishing the trim in the fo’c’sle, finishing the pilothouse,” says Oczkewicz. “Lots of gingerbread, we call it.”

Come spring 2021, Oczkewicz will take the Dan O north again for another season, and the distinctive boat will be an eye-catcher as well as salmon catcher on the bay. Whether he sells her and builds another remains to be seen.

“We want to keep building boats,” he says. “So we’ll sell this one if we can. That’s the strategy. Who knows? I may keep fishing until I’m 80.”