For freezer trawlers in the U.S., the processing experts at Carsoe deliver.

When big vessels want processing systems that work, whether it be head and gut, surimi and pollock blocks, shrimp, or any other high volume fishery, one of the first companies they talk to is Carsoe.

“I think for shrimp we are supplying the systems for all the big trawlers, maybe 100 percent,” says Jeppe Christensen, sales director at Carsoe, a Denmark-headquartered company with its U.S. division based in Seattle, Washington. “Certainly we are second to none.”

Shrimp has gained importance in Canada since the failure of the cod fishery, and is now a vital part of the Newfoundland fisheries. “We recently put a system on a vessel for Baffin Fisheries,” says Christensen. “It’s a combination shrimp and halibut trawler.” The $72.5 million, 262-foot vessel being built by the Inuit-owned Baffin Fisheries will be the largest trawler of its kind in Canada.

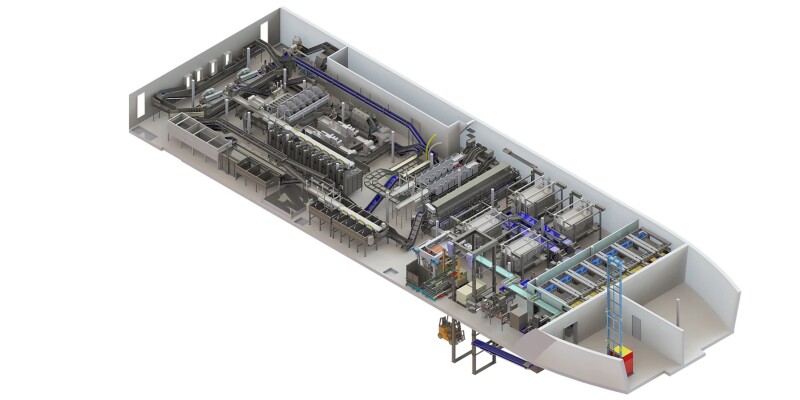

Carsoe systems are geared toward product flow and processing from the net to the freezer. “Every project is a one off,” says U.S. sales vice president Rueben Nielsen. “We talk to the customer about what they want and what they need.”

Nielsen and Christensen agree that while they pride themselves in building the best possible systems with top-notch products, about 80 percent of their business is rooted in personal relationships. “It’s about connecting with the customers and bringing our experience to the project,” says Nielsen.

Carsoe has a number of basic design templates for various fisheries: shrimp, pelagic, white fish, pollock & surimi, and crab. In the U.S., most of the systems the company sells are going aboard head and gut vessels fishing Atka mackerel and flatfish, and pollock and surimi vessels - primarily in Alaska. “We mostly do conversions,” says Nielsen. “There are so few new boats being built in the U.S. What have we had, three in the last six years?”

But the fact that Carsoe puts the systems aboard most of the new boats and conversions - the North Star, the Arctic Fjord, the Alaska Spirit, to name a few -- is the best endorsement of the company’s quality and service.

The head and gut systems like the one on the Alaska Spirit are pretty basic, according to Nielsen. They consist of sorting systems and H & G machines.

“It’s hard to talk about specific projects without the vessel owner’s permission,” he says. “Usually me or Henrik Rasmusssen go meet with the owners and builders, usually Henrik. They tell us what they want to do, and we create a system for them. Our biggest advances in the last 10 years have been in the automation of product handling later in the process, the hotels, palletizing and elevators. The early stages of sorting and putting fish in place for the machines is still labor intensive.”

The whitefish processing systems start with de-heading and bleeding, then moving to weighing, batching and the packing line. Carsoe offers fully automated freezing, hotel and palletizing lines that eliminate manual handling from the weighing station to the cargo hold.

Carsoe’s surimi and pollock system starts with an adjustable roller grader that can sort fish into 3 to 5 sizes, leaving the small fish out first while the larger ones continue till the end of the roller.

When the fish are filleted, workers inspect the product on a candling line. “A blower cleans water off the fillets, and the fillet spinners ensure uniform and effective inspections of fillets for parasites and faulty fillets on the candling table,” says the Carsoe website.

The system sends trimmings and rejected fillets to a mince packing line. Carsoe can provide a roe line and milt line for collecting and packing these products, while the guts and excess products are automatically transported to the fishmeal plant for further processing.

The Carsoe surimi line moves pollock fillets to a mincing machine, then to a wash that cleans all blood, small bones and impurities from the mince. The mince is then drained, mixed with other ingredients, and sent to a packing station. An electrical controlled pump system then delivers an accurate dosage of the mince to the scales before sealing the product and moving it towards the freezing line.

In port, Carsoe’s automatic elevator solutions transport products from the cargo room to the deck, and subsequently onto trucks or other transport. “This significantly reduces manpower and handling for offloading,” according to Carsoe. Christensen notes that a shortage of labor is driving the increase in automation.

Carsoe manufactures most of its machinery in a number of plants around the world. “We make most of the conveyors in the Seattle production facility,” says Christensen. “We make all our plate freezers in the UK and ship them where they need to go.”

But Carsoe doesn’t manufacture every component in its systems. “When we are putting together a system, we bring in pieces from other companies. We get our motors in Europe. We don’t get much out of Asia,” says Christensen.

Carsoe doesn’t make filleting machines for example. “We might use Baader or another brand,” says Nielsen. “Whatever is the right machine to put between our products.”

In many cases Nielsen will set up a system at the factory and run it to makes sure all the pieces work. “Or we might set it up on the boat and work with it there on site,” he says.

Once a system is built and installed, a Carsoe technician will go to sea on the vessel for its first trip or two. “We might go a couple of times to teach the crews and engineers,” says Christensen. “On a vessel like the Baffin Fisheries shrimp and halibut trawler, we would go out for a shrimp trip, and then again when they switch to halibut.”

In addition to a technician, Carsoe often provides a container of spare parts. “Whatever they think they need,” says Nielsen. “And there are parts that wear out, so you have what’s needed for scheduled maintenance. In some cases, if there’s a problem we can talk to the vessel and usually fix it. If necessary, we will send someone up to Dutch Harbor to meet the vessel.”

A busy time for Nielsen is when the big boat fleet returns to Seattle in the fall. “We are down on the boats for their maintenance, and making improvements,” he says.

Whatever it takes, Carsoe does what it needs to do to be competitive in keeping seafood moving on the boats that feed much of the world.