In 2017 the O’Hara Corporation began modernization work on the company’s recently acquired freezer trawler the Alaska Spirit. Originally built by Halter Marine Services in 1974, the Alaska Spirit is steadily being refitted with 21st century equipment and comforts.

“We work on her for about two and a half months every year during the offseason,” says Frank O’Hara III. In 2018, the company redid the processing room.

“They finished the season, and on the way down they tore out the old factory so when she got here (to Pier 91 in Seattle) we could go right to work,” says O’Hara. “This year we put in rebuilt Rapp hydraulic winches, replaced the old Yanmar gensets with Cats (C18s), and the Hanshin winch engine with a new Cat (C32). We also added a C9.3 for harbor, and to pair with the bigger generators when there is less load.”

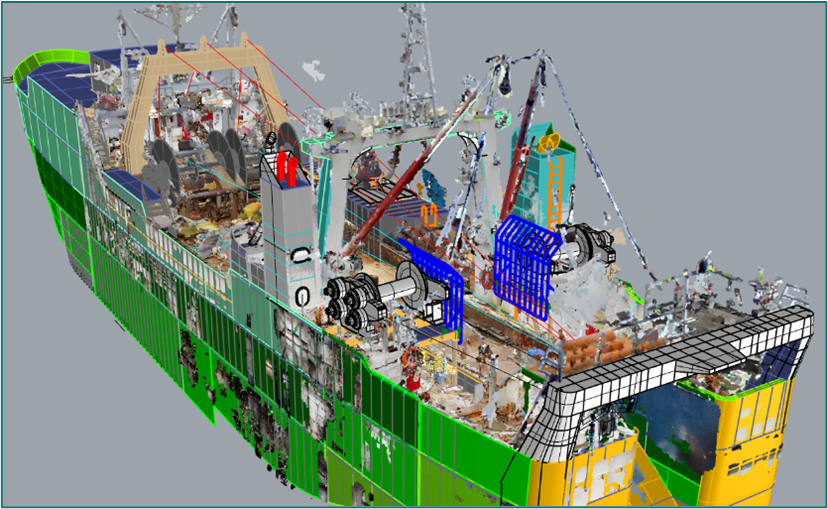

According to a press release from Elliott Bay Design Group, which has provided design and engineering services for the project, the Alaska Spirit also got new stacks for its main and auxiliary engines, reducing noise on deck from 130 decibels down to 85 dB. Having scanned the entire vessel, Elliot Bay is using sophisticated computer programs to continue designs and engineering for other improvement, including new deck equipment.

O’Hara Corporation initially installed a knuckle crane to replace the old-fashioned Burtoning gear used to handle the nets. “Next year we’re going to put in net reels and a forward gantry,” says O’Hara.

In addition to various mechanical upgrades, O’Hara points out that they are remodeling the crew’s quarters.

“There was kind of a hierarchy for bathrooms, and not enough for the crew – the processors,” says O’Hara. “We’re redoing those to make it easier for the crew, and we’re remodeling the crew’s quarters, getting rid of graffiti, making the staterooms someplace they can be proud of.”

Dealing with the threat of coronavirus among the 50-person crew has also guided some of the upgrades as well as operations.

“Everyone is wearing masks,” says O’Hara. “We’ve put in more hand sanitizing stations, keeping gloves clean. We’ve spread out mealtimes so we don’t have so many people eating at the same time.” According to O’Hara, the entire crew is quarantined in a hotel for two weeks, then given a covid-19 test and then all bused to the vessel at the same time.

“The boat is completely sanitized before they come aboard and them it’s just them,” he says.

When the boat gets back next autumn, she will go to a yard for much of the deck work and also get a new galley.

“Then she needs to make some money, right?” says O’Hara.