Amid looming trade wars and uncertainty about the price of wood, Supersede, a Phoenix, Arizona company, is offering boatbuilders an alternative to traditional marine plywood.

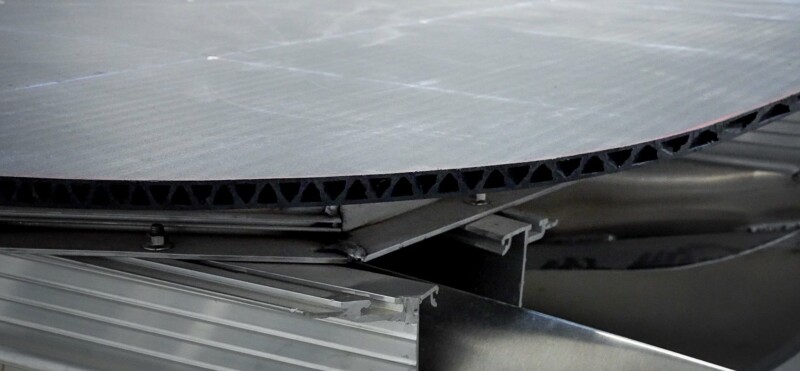

“Our Marine Board comes in ½-inch, 5/8ths, and ¾-inch thickness,” says Supersede owner Sean Petterson. “It’s stronger than marine plywood, has greater compression and 1.7 times the fastener retention.”

According to Petterson, who cofounded the company with Jordan Darling, Sean Petterson, and Shane Kenyon, the superior compression strength of Supersede Marine Board makes it ideal for decking. “It’s got double the compression,” he says. “And it’s strong on spans between the deck beams. So if you have a deckload of traps, or your setting traps and landing a lot of heavy stuff on deck, this will wear better than plywood.”

If there is any cracking of the fiberglass over the deck, plywood loses about 30 percent of its strength permanently once it gets wet, Petterson notes. “Our Marine Board only absorbs a small amount of water and doesn’t lose any strength,” he says.

While there are other manufacturers of lighter weight synthetic panels for vessels, Petterson feels Marine Board is superior in strength and fastener retention. “It’s the same dry weight as plywood, but it requires less fiberglass for stiffening,” he says. “We’re working on using a fiberglass infusion process with it, and that will be less glass, but we’re not there yet.”

Another aspect of Supersede’s Marine Board is that it is extruded in 4-foot wide panels. “We sell 8-foot, and 10-foot panels,” says Petterson. “But we can do as longs you want, up to whatever will fit on a truck. And because it’s being extruded, the cost is not that much higher. With plywood it’s more difficult to manufacture those greater lengths.”

Supersede is building its panels primarily out of recycled polypropylene. “We add some other material to give it structural consistency,” says Petterson. He points out that the FEA, Finite Element Analysis—a computer simulation that predicts how an object will behave when subjected to physical forces—can vary widely with marine plywood depending on numerous factors. “Because of our engineering we can keep our FEA within a tight range,” he says.

Petterson adds that because they are in the U.S. and have a steady productions system, they can offer consistent pricing and delivery. He reports that so far most of his boat building customers are in the recreational sector. “But we are getting inquiries from small boat builders, lobster boat builders in Maine. I can’t name names yet. Mostly we’re talking about using our Marine Board for rebuilding decks.”