A successful commercial fishery can often be gauged by new boats being built for that fishery.

Andy and Myles Cockrell of Cockrell’s Marine Railway and Little Wicomico Oyster Company LLC in Heathsville, Va., latest workboat under construction is a testament to that.

Over the past couple of years, Virginia watermen and state oyster aquaculture growers have annually harvested over 700,000 bushels of market-size oysters on public and private grounds, far ahead of any other state in the U.S.

Many attribute Virginia’s increased harvests going back to 1995-2007 era when experiments with cage aquaculture and cluster growing of oysters (spat-on-shell) were accelerated, and studies led to development of disease resistant oysters to counter the devastation in the 1980s and 90s of MSX and dermo, two oyster diseases that crippled the industry.

Virginia and Maryland efforts have contributed greatly to the comeback, too, with public rock oyster replenishment programs; creating and enlarging oyster reefs and sanctuaries; and rotating commercial harvest efforts on public oyster grounds annually.

It should not, however, be understated that Virginia’s success is also strongly tied to history and the Virginia General Assembly’s 1890s proactive legislature that split the state’s oyster grounds into public and private grounds, creating 100,000 acres of oyster bottom that could be leased and farmed under private usage. Last year, nearly 400,000 bushels of Virginia’s commercial oyster harvest came from private growers. The Cockrells’ are private growers who work leased grounds on Virginia’s Little and Great Wicomico rivers and on Ingram Bay.

The firm is building a 39’x13’6” fiberglass “super scow” to work in the Little Wicomico Oyster Company’s aquaculture cage growing business and to dredge seed oyster. This is the fourth oyster scow/garvey style boat that the firm has built for its own use.

“Every time I build one, I make it a little bigger and a little different,” said Myles. The new scow is expected to hold 115 loaded cages, and when working a dredge carry 400 bushels of seed oysters.

“I built this one with what I call a Cockrellized bow,” he said. “It is a garvey style but does not have the sharp corners that shape the V like on a standard blunted garvey bow. My new style has more rounded corners.”

Along with a slight garvey V in the bow, the boat also has three skegs built into the bottom. The skegs keep the boat steady when underway and keep it from moving around on windy days when the boat is being worked, said Myles.

The hull is constructed out of 1 1/4" Nida-Core polypropylene Honeycomb core sandwiched between two layers of mat and woven. Sides, bottom, stringers and bulkheads are all made from the product and covered with fiberglass. The hull is structurally sound with four stem-to-stern longitudinal stringers, two feet apart and three horizontal bulkheads positioned seven feet apart. The stern is given extra support as the 1 1/4" Nida-Core is covered with a 3/4" Coosa foam board and glassed over. A bracket will be incorporated on the stern to mount an outboard engine along with a Teleflex Extreme hydraulic jack plate to raise the motor straight up 6” when working in shallow water.

The boat will be powered by a 250-horsepower Yamaha outboard engine. The fuel tank, made from Vinyl Ester Resin and glass, is built under the ceiling near amidships and will hold 100 gallons of fuel.

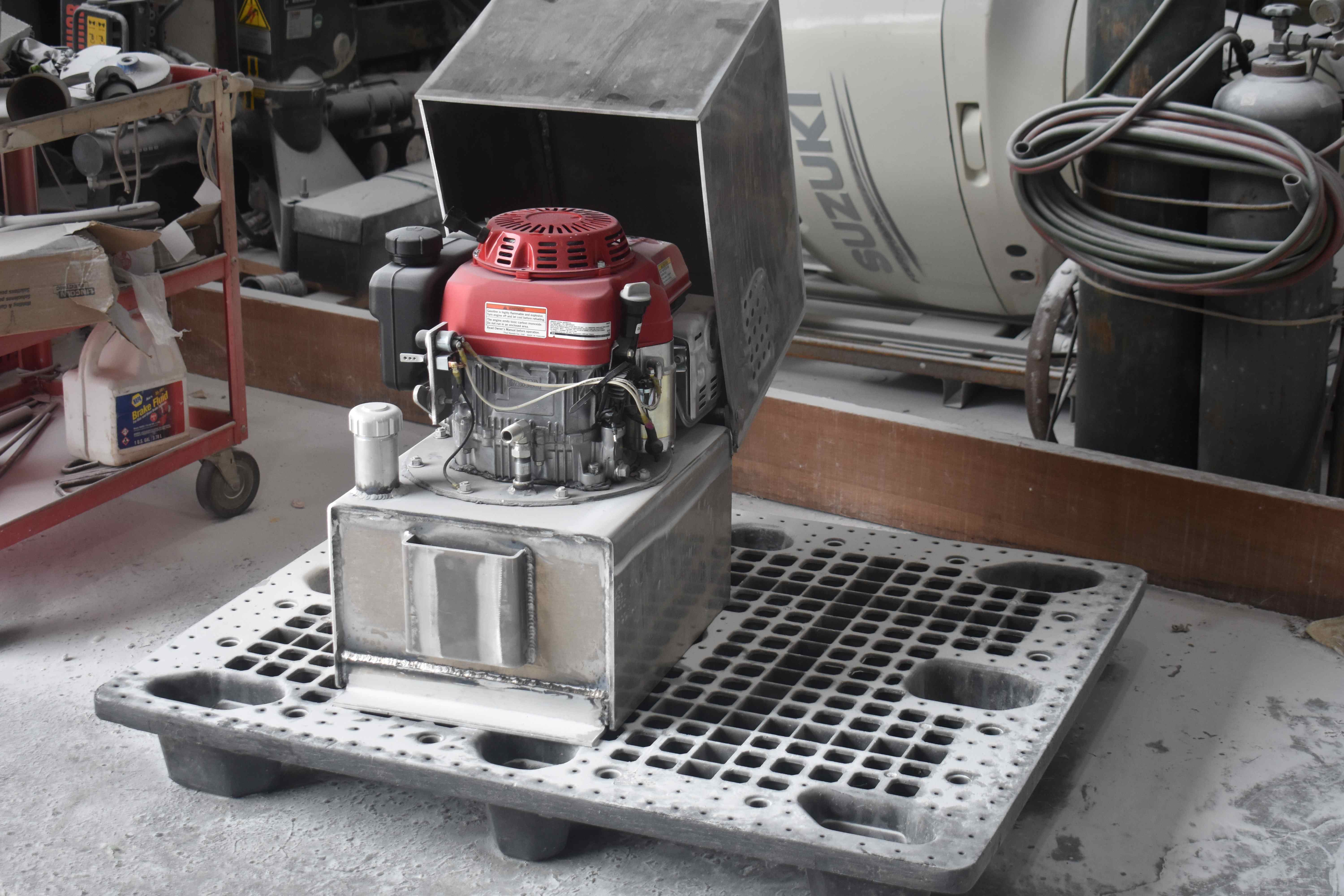

The steering is Teleflex Hydraulic Steering with Yamaha controls. Mounted on the stern deck will be a custom-built Hydro-Slave unit, which includes a GXV390 four-stroke Honda “lawnmower” engine. The unit is protected by an aluminum cover, pumps 15 gallons of hydraulic fluid a minute, and will run the winch and boom. The pump itself is mounted upside down in the hydraulic fluid tank which makes it a very compact unit, says Myles. The unit will be operated by a stainless-steel foot pedal, conveniently located near the foot of the helmsman. The hydraulic unit was custom-built by Jason Alderman of Warsaw, Va.

“The more licks you can make a day, means the more productivity,” said Myles. “We were getting our hydraulic units from a Maine firm, but the units only pumped 5 gallons of fluid a minute and the dredge would stall sometimes when coming up out of the water. This unit will snatch a hole in the water. She works fast and clean.”

The boat will also have an aluminum mast 20' high and an 18'-long gaff, fabricated at the boatyard from 4” Schedule 80 round aluminum pipe, and an 18'-long gaff made from 3” Schedule 80 pipe. The mast/gaff will be positioned near the stern, leaving work and payload space forward. The mast/gaff and stainless-steel winder are fabricated in-house at the railway and are used to haul the 3’x4’, six-inch-tall cages in and out of the water. The mast is rigged with 4 3/8" stainless steel cable. Two stays are attached to pad eyes on the stern bracket, and two ahead of the mast are fastened to a stainless-steel chain plate bolted starboard and port through the washboard and knee.

“As the business is growing, we are trying to grow with it,” said Myles. “Our new super scow will be a great addition to our fleet.”