Chesapeake Bay and Mid-Atlantic fishermen have been growing business relationships with Gulf of Mexico boatyards as a result of their interaction with the bay’s growing oyster fishery.

Mid-Atlantic and Southern commercial fishing entities are also tied to New England’s maritime infrastructure because of their longtime interaction in the Atlantic scallop fishery.

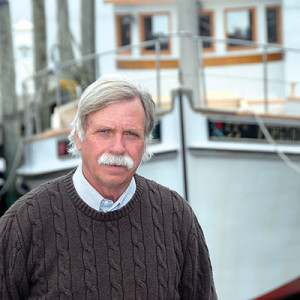

A case in point is Bill Mullis of B&C Seafood. in Newport News, Va., who has nine Atlantic scallop fishing vessels. Mullis is a past employee of a seafood firm in New Bedford, Mass., where he worked as a buyer directly from the boats establishing a broad relationship within the industry.

B&C Seafood was founded in February 2001 by Mullis and his longtime friend and fishing partner, Charles Olsovsky. Through his New England relationships, Mullis has worked closely with R.E. Thomas Marine Hardware of Hancock, Maine; Fairhaven Shipyard & Marina, in Fairhaven, Mass.; and Rose’s Marine Supplies of Gloucester, Mass. Fairhaven Shipyard is a major player in hauling and maintaining Mullis’ New England-based trawler fleet, he says.

Mullis says most of the large commercial fishing boats on the East Coast are now working out of New England, and there is a strong repair and maintenance infrastructure located in that region. On the Chesapeake Bay, however, large boats are no longer a main player in the fisheries. “The businesses that used to build, haul and repair the big commercial fishing boats are just not around here anymore,” Mullis says.

He recently had two projects that were equipped by trips north to get supplies. Mullis’ son-in-law and Gloucester County, Va., waterman Ryan Waddell purchased a Maryland-built 32' x 10' fiberglass head boat for $1,100. Mullis and Waddell have 300 acres of leased oyster ground on James River. They have been “pouring” seed onto the grounds for two years, and it is about ready to harvest, says Mullis. They are having the boat rebuilt to dredge oysters off those grounds.

Boatwright David Rollins of Poquoson, Va., was hired to do the rebuild. The large headboat-style house/pilothouse was removed, and a small traditional bay style house/pilothouse will be installed. “The old house took up a lot of space,” says Rollins. “Ryan will need as much workspace as we can get for him to work the dredge and carry payload.”

Rollins rebuilt all the structural elements under the ceiling and installed a new glass ceiling (interior floor). A new 6BTA 5.9 220-hp Cummings Diesel engine will be installed. The custom made 1-1/2" stainless steel shaft and cutlass bearings were provided by R.E. Thomas Marine Hardware. The hydraulic washdown and power steering pumps, two helmsman stations and steering rod for the rudder were supplied by Rose’s Marine Supplies.

An example of Mullis’ close relationship with northern suppliers was highlighted by his recent need for a shaft in his 55.6' x 14' x 4.7' Chesapeake Bay buyboat Linda Carol.

Linda Carol is a labor of love for Mullis. As a young man, he crab dredged aboard the boat under the tutelage of renowned skipper, the late Morris Snow. As a grown man, Mullis purchased and restored the boat out of his fondness of having worked aboard her and his love of the heritage and culture surrounding it.

In June, he had her up on the hard at York Haven Marina in Poquoson. Mullis was getting the boat ready for the 17th annual Chesapeake Bay Buyboat rendezvous in July when it was discovered the boat needed a new shaft. “The problem I was facing was where was I going to get a shaft made around here before the rendezvous in July?” he says.

He called his contacts at Fairhaven Shipyard, and they had the custom-made Aquamet 22 stainless steel shaft ready in two days and had it shipped to Virginia on one of Mullis’ seafood trucks coming south. Mullis had the shaft installed in the Linda Carol in less than a week. “It pays to know the right people in this business,” says Mullis.

Moving over to Reedville, Va., a recent visit to George Butler’s sideyard boatshop revealed a 12-foot skiff underway. Wooden boatbuilders usually start out their professional life building a skiff. When they move on to building and repairing larger boats, they never forget that first skiff.

When time and age take over, it seems universal that none can give up building boats and when they recall the emotion, excitement and reward that came from building that first skiff they often go back to their roots — building skiffs.

The skiff is for his wife, Becky, to row about on Cockrell Creek. The 12-foot skiff is made of white cedar with a tongue and groove bottom that he plans to fiberglass. It has a tuck stern similar to the style built on late 19th-century sailing schooners where the deck line extends farther aft than the waterline. George Butler’s retirement and the sale of the Reedville Marine Railway was announced in an earlier column.

A boatbuilder’s life is often measured in skiffs!