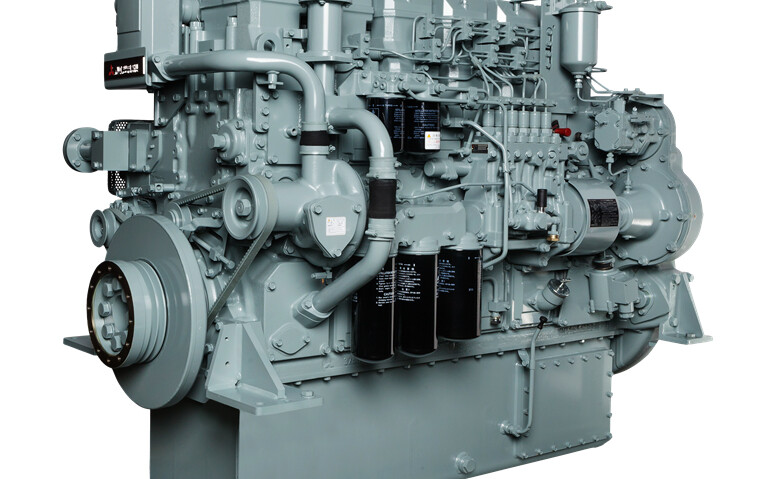

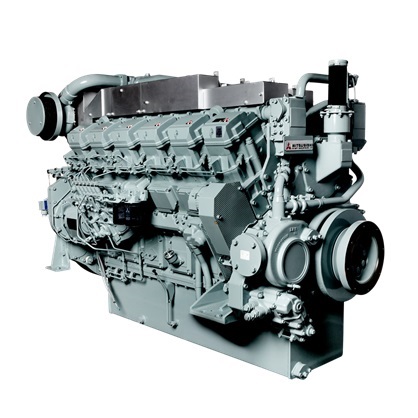

Mitsubishi designs manufactures and delivers engines for the most rugged applications, such as tugboats, push boats, and fishing vessels. As a result, these engines have big displacement and a lot of engine mass. They are specifically designed for applications where operational reliability is key, such as fishing and towing customers. The market these days is all about downsizing and getting more power out of smaller engines, which is indeed the right approach for many applications. However, Mitsubishi targets the heavy-duty applications market, which has different requirements. This makes the application for which the engine is used one of the most important considerations when buying, designing, and manufacturing an engine.

Why do today’s commercial fishermen prefer mechanically controlled engines

Historically, all engines were mechanically controlled. This means there’s a lot of history and knowledge in the industry about how to service and maintain mechanically controlled engines. Another option, namely, electronic controls, came into the US in 2007, when EPA Tier 2 was introduced. To meet these emission requirements, most engine manufacturers went to the electronic engine as it allowed them to more precisely control the mixture of fuel in the air and meet these requirements. However, Mitsubishi noticed that although emission requirements have changed over time, mechanical engines are still the engines of choice for most customers.

Although Mitsubishi provides mechanical and electronic controls, they noticed that customers were asking for the mechanical controls as they were easier for them to manage and get an engine back up and running with a few simple tools. With an electronic engine, they would need an experienced service technician to come on board and diagnose what’s going on in order to correct it. The mechanical controls option is of particular interest to commercial fishermen as it gives them a sense of confidence and belief that they’ll be able to get the vessel going.

One reason commercial fishermen choose the mechanical option is that many fishing vessels that Mitsubishi repowers are single-screw vessels that don’t have the option of a backup engine to return them to their home port safely. Furthermore, fishing boats have to deal with sharp-seasoned windows, so they cannot afford to wait for a technician to fix a sensor or electronic engine. Ultimately, it’s all about being self-sufficient, getting the engines back, and operating. Interestingly, it is also the preferred choice for inland operators, for example, the Mississippi River, where the bank is no more than a hundred yards from where they’re located, providing easier access to technicians to make computer repairs.

As a result, Mitsubishi has to apply changes to tweak their engines with every new Tier. This means that internal combustion components are slightly modified for every new emission level.

Mitsubishi’s engines operate from 1,400 rpm to 2,000 rpm. Mitsubishi’s combination of engine speed, piston speed, and engine torque results in the best design for heavy-duty rugged fishing and towing applications.

It’s important to consider the torque when selecting engines for a towboat or push boat. To understand torque, let’s discuss the basics: the pressure created over the piston head generates a force transmitted to the crankshaft through the connecting rod. The distance between the crank journal and main bearings is the arm that allows the creation of momentum or torque (expressed as force times arm). It represents energy measurement unaffected by time, while power is expressed as torque times angular speed, where speed depends on revolutions per minute (rpm).

How much torque this engine can produce is often forgotten when comparing engines based on power. For example, an engine with 600hp@1300rpm produces a torque of 3,287 Nm at rated power and speed, while an engine with 600hp@1800rpm produces 2,374 Nm, which means 28% less torque.

Mitsubishi uses two other wear indicators: weight per power and liters per power. These are piston mean speed and break mean effective pressure (BMEP). The engine speed and the stroke length will determine the piston's mean speed. Mitsubishi designs the engines to be robust, and it is possible to see that engines with long strokes have a lower rpm to ensure a controlled, healthy piston mean speed. Similarly, Mitsubishi tries to keep the BMEP in a controlled and healthy range through the engine’s geometry for high displacement. Additionally, with a good design and proper matching of the turbocharger and injection system, Mitsubishi can offer mechanical, simple, and reliable engines that meet worldwide emission regulations and meet customer requests regarding performance and fuel consumption.

Mitsubishi's distributor network includes Cascade Engine Center for the West Coast, Alaska, and Hawaii. Laborde Products takes care of the Gulf of Mexico, the East Coast, and inland waterways. Frontier Power is on Canada’s Pacific side outside the United States, with Sansom Equipment covering Canada’s Atlantic dealings. Mitsubishi’s distributor and dealer coverage across the U.S. and Canada allows for parts and service support that is strategically positioned to meet the needs of all customers.

Beyond the spare parts available from dealers and distributors nationwide, they can be ordered from warehouses in the United States and Japan. Mitsubishi Turbocharger and Engine America (MTEA) is responsible for distributing Mitsubishi Marine Propulsion Engines in the Americas, including Canada, Mexico, and Central and South America. MTEA is a part of Mitsubishi Heavy Industries Engine Turbocharger, LTD, a Global Corporation headquartered in Tokyo, Japan, and a major division of Mitsubishi Heavy Industries. Mitsubishi has been manufacturing marine diesel engines for more than 70 years.