Marine Hydraulic Consultancy has developed the new Drifter drum for Bristol Bay boats. Alan Severns, owner of Marine Hydraulic Consultancy in Poulsbo, Wash., identified a need in the Bristol Bay salmon fishery for a new kind of net drum.

“What was happening is that when fishermen were trying to set their nets fast, they couldn’t free wheel the drum fast enough. On a lot of drums, you have just a 1-inch freewheeling ball valve that can’t handle setting at the speed these boats can go. You end up blowing up your motor.”

Severns notes that downtime for repairs can mean lost fishing opportunities, and in a season that only lasts a month, few fishermen can afford that. “What we did was build a drum that can freewheel without spinning the hydraulic motor and incorporated a disc brake to give you full and safe dynamic braking control of the drum.”

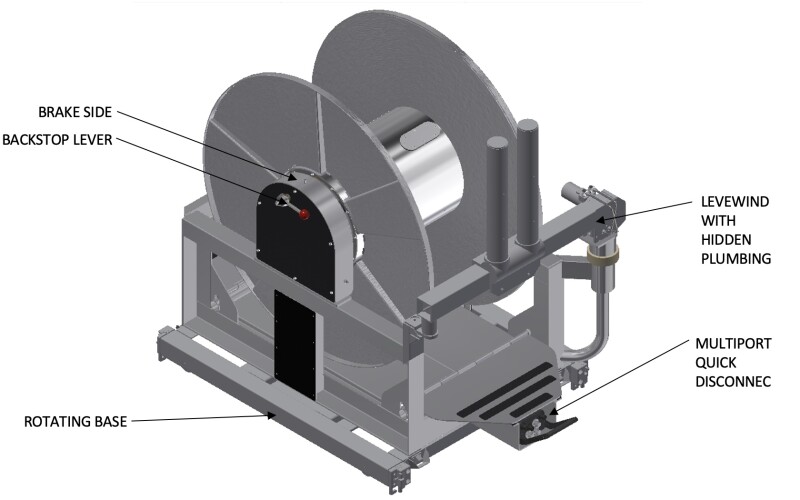

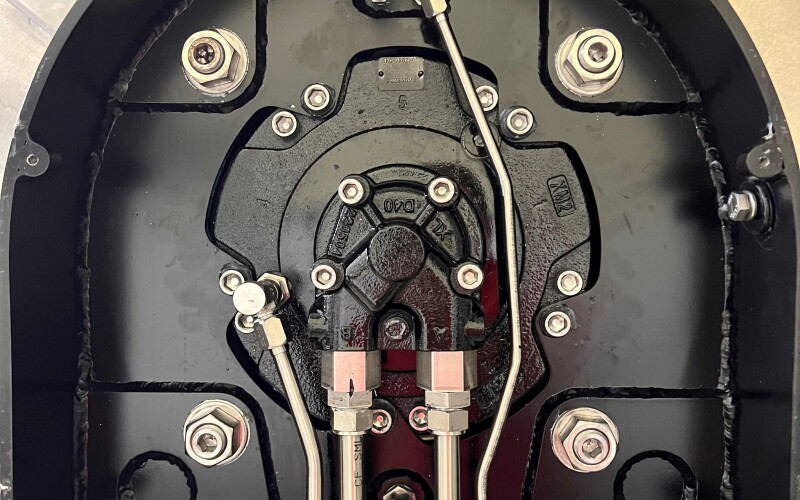

Severns calls the new drum the Drifter. He set up one boat for the 2023 season with the new drum and has built another one for a second boat. He’s made a number of changes to the standard drums, including adding a clutch to the hydraulic motor and recessing both into the core of the drum. By adding a clutch, Severns’s design protects the radial piston motor from failing when freewheeling.

“The drive mounting arrangement is accomplished by using a centerless bearing design where four threaded track roller bearings are installed on either side of the drum and ride on the inside diameter for the drum core,” he says, noting that the centerless bearing design provides for an extremely compact bearing support, enabling the drive components to be installed on the centerline of the drum core.

“What you have in most current designs is a shaft that rests on a pillow block bearing on one side and the hydraulic motors acts as the bearing for the other side. With ours, the bearings support the drum,” says Severns. “The motor and clutch only supply torque. All of the radial and dead loads are supported by the cam follower bearings. This is a big benefit as no loads are taken by the expensive hydraulic motor. With all that inside the drum, it is clean and out of the way, so your net doesn’t get caught on it.”

Severns also built a motor that he believes is better suited to Bristol Bay boats. “The motor is 25 percent lower displacement than the norm,” says Severns. “On Bristol Bay boats, you can only generate so much flow,” says Severns. “So, we’ve reduced the flow by 25 percent, and instead, increased pressure by around 25 percent.”

Severns designed the Drifter with shallow water sets in mind. “When you’re fishing in three feet of water, or less, this lets you get up on step and set. With this drum, boats can get in where the fish are and get back out to deeper water. You control the drum with a disc brake; there’s a lever for the brake on the side of drum that you use to slow or stop it.”

Last year, Roger Mikkelsen put one of Severns’s drums on his new Bristol Bay boat, the F/V Abundance. “He did well with his,” says Severns. “And we have built another for this next season.”

According to Severns, Mikkelsen’s boat and the next one are both thru-pickers. “With stern pickers, you can have a taller, narrower drum, but with thru pickers, the drum has to be able to run under the wheelhouse, so the drum has to be lower and wider. Also, you have to put the drum on a rotating base to turn it in case you want to haul from the stern or the bow.”

With the lower, wider drum, Severns has installed a level wind. “It’s a standard Maritime Fabrications level wind called a Bowser Pivot. It swings 270 degrees out of the way when you’re setting. What we did differently was put the hydraulic hoses inside the support and used a rotary manifold inside the tube, so they are not coming from the top and creating another place for your net to get caught - it’s a minor alteration but very well received.”

In addition to the motor for hauling, the clutch for freewheeling, and the disc brake to control the speed of the drum, which Severns says can be over 400 rpms, his drum has a lock to allow a vessel operator to tow on it. “There’s a dog on it, so you can lock it if you have to pull on the net,” he says.

Severns believes it is only a matter of time before his new drum design catches on, enabling fishermen to harvest more fish, avoid costly downtime, and work in safer conditions.

“I was the guinea pig for the drum,” says Roger Mikkelsen, who launched his new boat Abundance for the 2023 season. “I never blew a motor,” says Mikkelsen. “But I can tell you that the drum performed as expected. I like to work in shallow water, sometimes inches. We set on step at 20 knots. I can tell you it’s a white-knuckle experience.”

Mikkelsen has two 570-hp FPT engines and HI-500 jets powering the Abundance, and with the speed he gets, the disc brake on the drum is his favorite feature. “I use it a lot, so we don’t get backlash setting at that speed.”

Mikkelsen ended up as the guinea pig by chance. He had already engaged Severns to do the hydraulics on the Abundance. “Then he told me about the drum and I was interested. Then he told me the price.” Mikkelsen and Severns came to an agreement that still cost Mikkelsen thousands more than he had projected. “We collaborated with Maritime Fab in LaConner, I added a quick disconnect for the hydraulic hoses. I’ve got the revolving base, and my deck is flush so I can slide the drum from the bow to the stern.”

Overall, Mikkelsen has no complaints. “I built most of the boat myself, so that saved me a lot of money. But I bought the best equipment I could, so I guess I about broke even.”