The late Arthur L. Helbig built fiberglass deadrise workboats in the 1970s and '80s under the trade name of Gloucester Marine at Clay Bank, Va.

Helbig, John Collamore III of Hulls Unlimited East Inc. in Deltaville, Va., and Whitey Laurier of Glass Marine of Hayes, Va., all came to Virginia about the same time and started turning out working craft modeled after traditional wooden deadrise boats.

In the beginning, all three struggled to find direction in the Chesapeake boatbuilding marketplace, where wood had always been king and where watermen were skeptical of fiberglass as a boatbuilding material.

One of Helbig’s first commercial fishing boat customers was waterman Kenneth Bonniville who in 1984 had Gloucester Marine build him a boat named Dayspring. Kenneth works the boat to this today and in those early years he worked it with his son Jeremy.

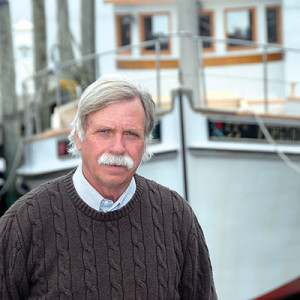

Jeremy, now 49, owns Crabs Express Inc. in Gloucester, Va, a retail seafood business. He is also a commercial fisherman and owner of old Jordan Marine railway at Gloucester Point, Va.

“I learned the maintenance value of fiberglass boats compared to wood boats at an early age,” said Jeremy. “My father was one of the first in our area to go to a fiberglass workboat. I grew up working on a fiberglass boat and that is what encouraged me to stick with glass boats.”

As owner of Jordan Marine, Jeremy has a 43’ x 15’ x 3.5’ fiberglass garvey style workboat under construction that he is going to use himself to harvest seed oysters on James River and to plant shell and seed. He leases 15,000 acres of Virginia oyster grounds on the York and James rivers and Mobjack Bay.

“I learned a lot about working with fiberglass while working on my father’s boat, but I learned much more firsthand in 2002 when I was having my own boat, Jaqueline Alice, built in Salisbury, Md.”

Jeremy has one of those boatbuilding horror stories. The builder was going under financially before Jeremy’s boat was half completed. “I moved myself to Salisbury and worked side-by-side with the builder until my boat was finished,” he says.

The Garvey

The 43-foot garvey has 18-inch wide washboards that allow oystermen to stand on and work comfortably and safely while tonging for seed oysters with hand tongs. The boat will also be used to dredge oysters. A wheelhouse is positioned aft, while a mast/boom for dredging will be installed forward of the engine box. “I wanted an aft pilothouse so I can see what’s going on with my crew when we are planting,” says Jeremy.

The garvey is made out of a reused hull taken off a pleasure boat, and the wheelhouse came off a commercial crab boat that Jeremy purchased from a boatyard owner after a railway bill was left unpaid.

The components are put together with layers of polyester resin and fiberglass mat, and roving cloth. The hull is 3/4” thick, with the sides 3/8” thick. The deck floor forward of the engine is several layers thicker than the rest of the floor. This provides more strength in that portion of the floor where shovels will be scraping against when off-loading oysters.

The garvey will be powered by a rebuilt 6-71 Johnson and Towers diesel engine, rated at 235 h.p. at 2100 rpms. It has a Twin Disc clutch working through a 2:1 reduction gear with a 2” stainless steel shaft. The prop is four-bladed with a 26” diameter x 24” pitch. The custom-built fuel tank, made of plastic composite material, holds 100 gallons of fuel.

Glass-over-wood

The yard has two boatbuilding stalls, one of which is occupied by a wooden boat named Guinea Girl, which is getting complete glass-over-wood coatings and a new house/pilothouse. The round stern, 42’ x 12.5’, vessel was built in 1968 by the late Lody Davis, a well-known Gloucester County, Va. wooden boatbuilder. The boat belongs to Jeremy’s son Trevor Bonneville, 27, who works the water independently of his father.

Wess Robbins built the new house on Trevor’s boat out of African mahogany wood and coosa composite board and is being glassed over using West System Epoxy.

“I’m a fifth-generation waterman, and my son is the sixth generation,” says Jeremy. “Most all of my descendants worked out of wood boats but we have found that fiberglass works too and, like I said before, I learned at a young age the tremendous advantage that fiberglass has over wood when it comes to maintenance.”