Caudwell Marine is a U.K. company intent on bringing its new 300-horsepower diesel outboard to the workboat world, including commercial fishing vessels.

“We understand that we need to prove ourselves,” said Caudwell’s commercial director, Peter Ordway. “And we’re ready to work with people who want to buy our outboard. We’re currently preparing for our field trial program to prove the product with real users in real-world conditions, and offering partners an attractive commercial package to take part.”

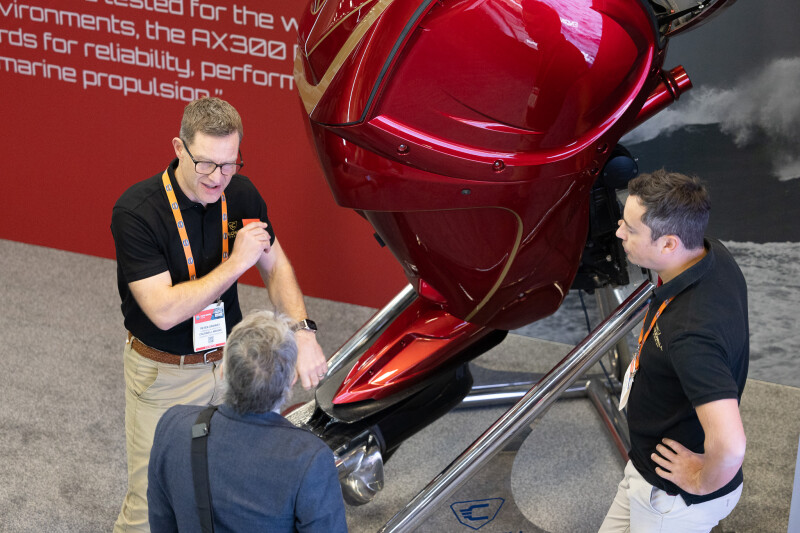

Ordway and the Caudwell team brought their diesel to Pacific Marine Expo with the intention of presenting commercial fishermen who use outboards with a high-power, lower-maintenance, and safer option to gas outboards. “This is for people who put a lot of hours on an engine,” said Ordway. “We’re looking for people who spend a lot of time on the water, and we think they can pay back the cost of this engine in 18 months.”

On the top end, the 1,043-pound Caudwell engine starts with a cast-iron long block, made by VM Motori in Italy. “We marinize that and that’s bulletproof,” said Ordway. “Then, in the middle, we have a ZF transmission. The lower unit and steering system are our design, but made by ZF.”

Ordway noted that the lower unit articulates. “The motor itself doesn’t move,” he said. “The lower end turns 35 degrees in each direction, and it's angled down, you see, to help the vessel on plane and maintain power in the turns.

“At top speed, 4,000 rpm, the Caudwell burns about 63 liters (16.6 gallons) an hour,” said the company’s applications engineer, Mike Jones. “But if you come back to 3500 rpm, it drops down to 30 to 40 liters. The extra 2 or 3 knots you get at top speed, you pay a lot for.”

Jones noted that the engine’s torque curve offers a lot of power and maneuverability at low speed. “It’s a very torquey engine,” he said.

Besides performance, the Caudwell has a lot to offer in terms of maintenance. “Each of the subsystems is built for 5,000 hours,” said Ordway. “But of course, in extreme conditions, heat or cold, it will be more between 2,000 and 3,000 hours. But it’s built for durability with 250-hour service intervals.”

The Caudwell team is hoping that Cascade Engine Center in Kent, Wash., will distribute the new diesel. “We’re putting a lot into support,” said Ordway. “We have all the parts here, and we’re looking to start with a small number of boats and train technicians. We know that in some fisheries the seasons are short, and in some cases, downtime can cost you the season. We want to be ready because we know that 50 percent of our success will be, 'Does it work?' And 50 percent will be, 'Can we get parts for it?'”

With what he’s offering in terms of performance, maintenance, and safety, as well as pricing, support, and guarantees, Ordway is aggressively looking for fishermen who want to see if the advantages of diesel outweigh the initial cost.