Unlike U.S. Fishermen, Canadians have the option of building boats overseas, but that doesn’t come without challenges.

In 2025, Baffin Fisheries Coalition, an Inuit-owned fishing company based in Nunavut, Canada, took delivery of what is currently the largest commercial fishing vessel in the country, the 80-meter-long, 18-meter-wide Inuksuk II. Inuksuk (pronounced Inukshuk) is the Inuit word for the pretend people—piles of stones stacked on the tundra in a roughly human form to help hunters find their way across the featureless arctic landscape.

“We operated the Inuksuk I for 25 years,” says former Baffin Fisheries CEO, Chris Flanagan. “Then we sold it to a company in the Faroe Islands, where it was built. Sort of a homecoming for it, and hopefully it will see another 25 years of fishing.” In 2020, Baffin Fisheries ordered its new boat, the Inuksuk II, from Tersan Shipyard near Istanbul, Turkiye.

Most U.S. fishing companies must build their boats in the U.S., with some exceptions, according to the Merchant Marine Act of 1920, commonly known as the Jones Act, with limited exceptions that require extensive waivers and regulatory approval, while Canadian companies can have boats built anywhere. Several eastern Canadian companies have opted to have their boats built by Tersan. Flanagan points out that having a boat built overseas involves many complications, especially during COVID and the Russian invasion of Ukraine. “One of our first problems was with the steel,” says Flanagan. The mill in Ukraine that was going to supply all our steel was one of the first places bombed by the Russians, so right at the start, we had to find another steel supplier.”

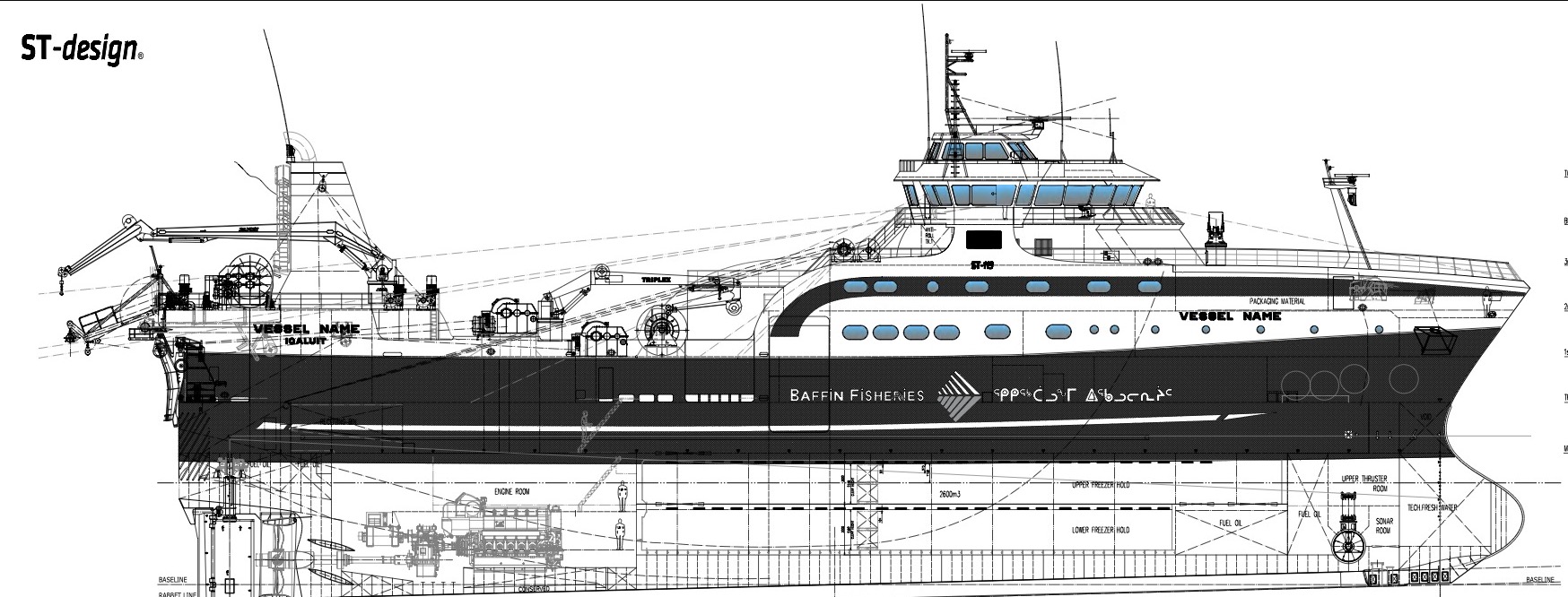

According to Flanagan, Baffin Fisheries contracted the Norwegian naval architecture company Skipsteknisk to design the new boat. “We were about to sign with another naval architect,” he says. “But the day before we signed with the other company, Skipsteknisk called us with some new numbers, so we went with them.”

Skipsteknisk designed an 80-meter (262-foot) vessel for shrimp and turbot trawling in polar and subarctic regions. “Baffin Fisheries is a three-vessel company,” says Flanagan. “So this is a big investment for us.” He explains that the company is owned by five hunter and trapper associations from five different communities, and profits from the company are shared among them and members of the communities. “The owners tend to be on the conservative side in terms of risks, and so we went with proven designs and technology.” He notes that several other Skipsteknisk-designed boats had been built for eastern Canadian fishing companies. “The Atlantic Enterprise, the Northern Osprey II, and the Calvert were all designed by Skipteknisk, and the Osprey and the Calvert were both built by Tersan.”

Flanagan adds that rather than seek a competitive edge, the owners of the Calvert—Ocean Choice—and the Northern Osprey III—the Labrador Fisermen’s Union Shrimp Company—helped Baffin Fisheries understand the process and potential pitfalls of having a boat built abroad.

“Because we were building during COVID and dealing with crazy inflation, we had to sign a more flexible contract with Tersan,” says Flanagan. “There were buffers built in, like variation orders, where you might have to make changes where a pipe and a conduit conflicted, for example. Usually, that’s no cost, but the yard had to recover its costs on those. Then we had to account for currency exchange rates and increased management costs during the pandemic.”

Baffin sent its own management team to Turkiye at significant cost, but Flanagan believes it was worth it. “What the company and the designers sell you is a turnkey vessel. They will deliver a boat with the beds made and the cutlery in the galley, so you get a false sense of security. But we learned from others that need your own team there to make sure everyone understands things like how the wires are run, and other systems are set up.”

The team also inspected equipment and materials. “For example, we ended up getting Chinese steel,” says Flanagan. “We were concerned about the quality, but there are lots of international regulations, and we had our own guys right there when it arrived to make sure it met the required standards.”

The team stayed together to reduce exposure to COVID, and whenever Flanagan went to the yard, he would get a COVID test. “They would come to our hotel rooms and do a quick test,” he says. “It was very efficient.”

Surmounting the many obstacles they encountered, Flanagan and the Baffin Fisheries team watched the vessel come together. Like many other yards, Tersan assembled the hull from modules, connecting them one section at a time until the hull was complete.

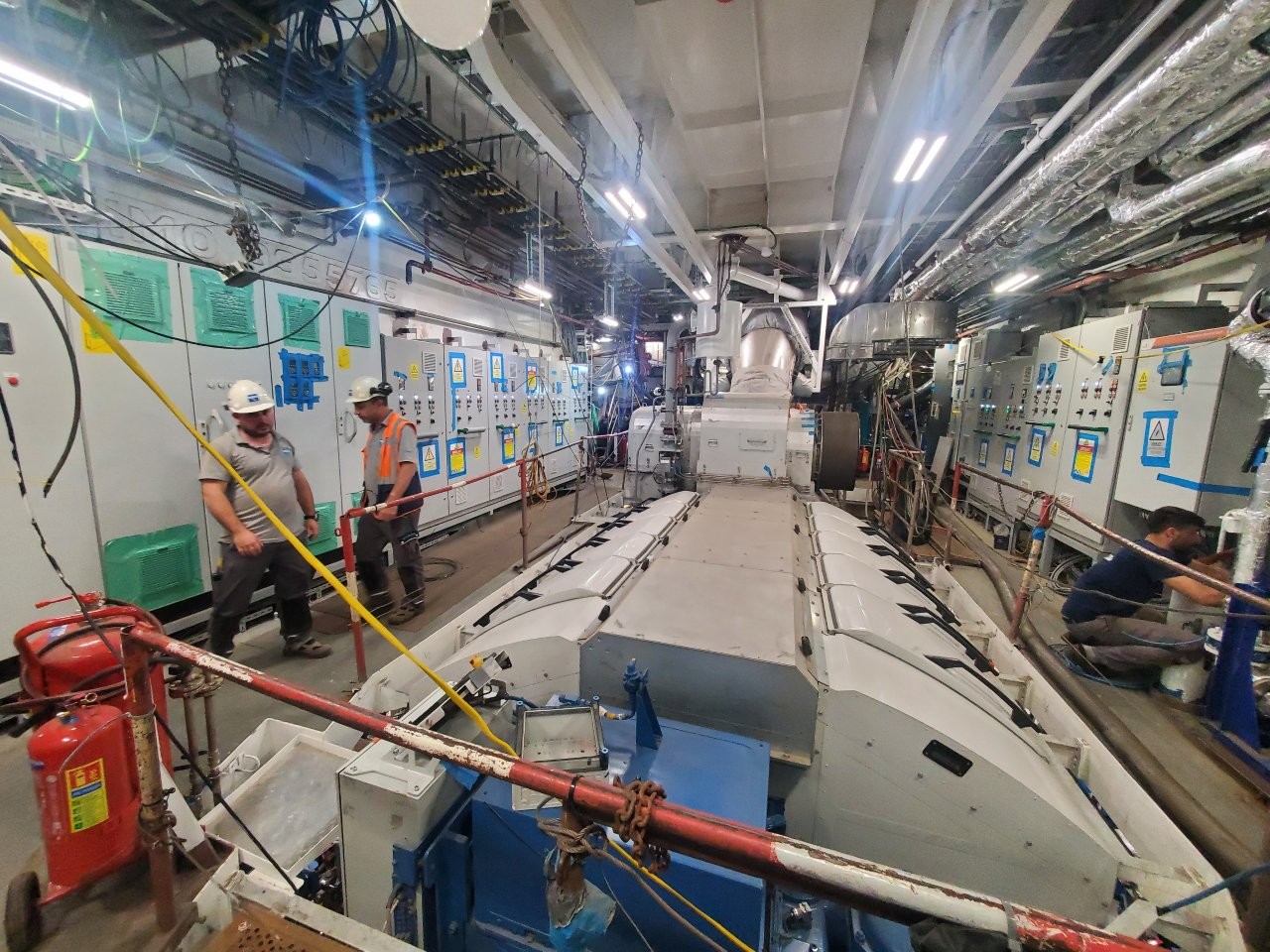

“We didn’t want to try a new-fuel engine,” says Flanagan. “We went with the Wårtsilå 10V31 diesel, which is a very fuel-efficient engine, and it can be converted to other fuels, if alternate fuel storage technology becomes practical. But for 2025, Fuel consumption has been excellent. The Inuksuk II is consuming less fuel than smaller trawlers with 40 percent less capacity.”

“Wärtsilä's full scope for the vessel also includes the gearbox, controllable pitch propellers (CPP) and the ProTouch Control system,” says Wårtsilå spokesperson Isabella Alder. “Fishing companies are looking to adopt technologies that lower emissions and reduce the environmental impact of their operations, while maintaining profitability.” According to Alder, the Wärtsilä 31 engine’s high fuel efficiency and reduced emissions make it ideal for fishing vessels. “Another feature of the Wärtsilä 31 is the modular design,” she says. “This enables a significant reduction in maintenance requirements and costs. It retains high efficiency and environmental values throughout the entire lifecycle of a vessel.”

In addition to the 8,000-hp Wärtsilä main, the Inuksuk II also has two 1,370-hp Yanmar auxiliaries—that can also provide power to the drive train in an emergency—and a Scania D109 M backup genset.

Staying with the theme of proven technology, the Inuksuk II has a Carsoe factory to process, freeze, and pack shrimp and turbot. “We’re also looking at cod, as those stocks appear to be moving north,” says Flanagan. Carsoe, based in Aalborg, Denmark, has put its factories on virtually every shrimp vessel in eastern Canada, and the system on the Inuksuk II will feature the company’s automated palletizing system. “Robots will be doing the lifting and sorting that people used to have to do,” says Flanagan. “And everything will be on pallets, so that will make offloading faster and easier. In the past, every box would have to be handled individually.”

The vessel has the capacity to catch and process 65 tons of shrimp or 55 tons of turbot daily, and the freezer hold will carry 900 tons of shrimp or 1300 tons of turbot when full. Deck equipment includes an electric winch package supplied by the Spanish company, Ibercisa. “The three electric trawl winches are designed to fish as deep as 1,000 meters,” says Flanagan. He notes that as the winches pay out wire, they generate electricity that is fed back into the vessel’s grid. The Ibercisa package also includes 15 other winches for handling the gear, a net reel, and anchoring and mooring winches.

The Inuksuk II uses a Scantrol system to keep the net fishing at maximum efficiency. Other electronics in the spacious wheelhouse include Simrad SN90 and ST90 sonars, an Olex bottom builder system, and an impressive array of top-of-the-line navigation, radar, communication, and monitoring systems.

According to Kelly Kilabuk, chairman of Baffin Fisheries, the “new vessel will allow us to increase benefits to Nunavut communities and improve employment opportunities and working conditions for our fishermen.” The boat is designed to accommodate 38 crew with a level of comfort unknown to earlier generations of fishermen. With 23 staterooms, most accommodating two crewmembers, a spacious mess hall with buffet service, a TV lounge, a hospital, and more. “There’s a weight room and a sauna,” says Flanagan. The Inuksuk II expects to attract and keep a skilled workforce, providing more opportunities for the people of Nunavut, as well as Newfoundland.

Flanagan reports that the vessel made eight trips in 2025. “The biggest trip was a turbot trip in the high Arctic, Area 0A, which landed 1,140 tonnes of product,” he says. “There are a few minor procedures to work out to get to 1250, or even the technical maximum of 1,300.”

While building overseas offered some advantages for the Inuit-owned coalition, it also had its complications. “It was a big investment,” says Flanagan. “But the Inuksuk II is already one of the top-performing fishing vessels in the North Atlantic.”

On another level, literally, the Inuksuk II has a unique feature that speaks to its community-based ownership. On top of the wheelhouse sits a conference room that will accommodate meetings such as those of the board of Baffin Fisheries Coalition. Wrap-around windows provide a panoramic view of the Arctic landscape and seascape, and the towering vessel is a highly visible marker itself, like the stone inuksuks of the tundra, helping the Inuit people find their way in the world.