The Deckelman brothers, Mort and Bill of Deckelman’s Custom Aluminum Boats in Rock Hall, Md., are forerunners in the building of Chesapeake Bay commercial fishing boats out of aluminum alloy.

The classic Chesapeake Bay wooden deadrise workboat was the standard on the bay for generations, until in the 1970s, Virginia and Maryland fiberglass builders introduced fiberglass deadrise boats. As the price point on a wooden boat began to move closer to fiberglass deadrises, some watermen began to make the shift.

The classic deadrise hull style, however, made of wood or fiberglass, was time-tested, and the popularity of the hull shape did not change. During the 1980s and 90s, fiberglass builders began to make inroads into the Chesapeake Bay workboat market, and, along about the same time, a few boatbuilding pioneers were experimenting with building deadrise boats out of aluminum.

In Virginia, Coddie Carrington and John Fowler of Delta Marine in Deltaville, Va., built in 1982 one of the first deadrise commercial fishing boats on the bay out of aluminum alloy. It was modeled after the classic wooden Deltaville deadrise hull. (See National Fisherman, Feb. 1983, pgs. 73-74). It was a one-off – the only one the firm built – but it was recognized then by area watermen that aluminum made for a good boatbuilding material, requiring less maintenance and providing more durability than wood. The Carrington/Fowler boat is still working in Virginia’s commercial fisheries to this day.

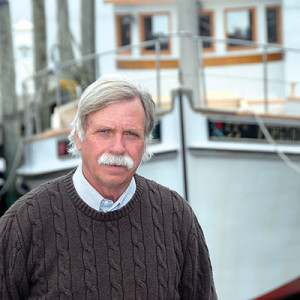

The Deckelmans took the aluminum boatbuilding experiment to another level. Mort, 49, started welding at his father’s boatyard when he was 12 years old; built his first boat out of aluminum when he was 16; and in the 1990s introduced his own aluminum deadrise version to the commercial fish boat marketplace. Over time, Maryland watermen have responded positively to a shift from wood and fiberglass to aluminum. The yard builds aluminum deadrise boats in the 20-foot to 50-foot range, and many Deckelman boats are working in the bay’s three major fisheries of oysters, finfish, and crabs.

Most recently, the firm has seen a demand for aluminum scows and has a 32-footer underway in the shop. The boat is for a Baltimore, Md., fyke net fisherman who will use the boat to catch bait fish in Maryland’s blue crab pot fishery. The 32’x10’ scow will be outboard powered. Mort says watermen commonly use 300 hp outboard engines for power.

“The 32-footer will fly with a 300 h.p.” say Mort. “The boys do not have far to go to get to the fishing grounds, but they like to get there and get back home quickly,” he says.

The scows range in size from 20-foot to 32-foot with the 28 footer being the most popular length. Deckelman uses 5086 1/4” aluminum alloy plate for the sides and bottom; 5/16” for “bigger boat bottoms;” and 1/2” and 5/8” for the keel and structural elements.

The advantage of 5068 aluminum sheets is that they offer less weight with excellent welding performance, contributing to the boat's overall light weight, improved fuel consumption, and less maintenance cost than traditional wooden boats, says Mort.

The Deckelmans keep a Deckelman (aluminum) deadrise 34 named the “The Rock” for use around the boatyard and to compete in annual workboat docking contests. The Rock, built in 1999, is annually used to compete in docking contests around the bay in the 31-foot to 40-foot length division.

At the annual Watermen’s Day celebration at Rock Hall in July, the Deckelmans got upset in a run-off docking contest by Jake Jacobs of Baltimore in the Outlaw, who tied the meet record of 16 seconds, held by Jacob and Mort Deckelman since 2017.